αGEL Solutions

Vibration Control

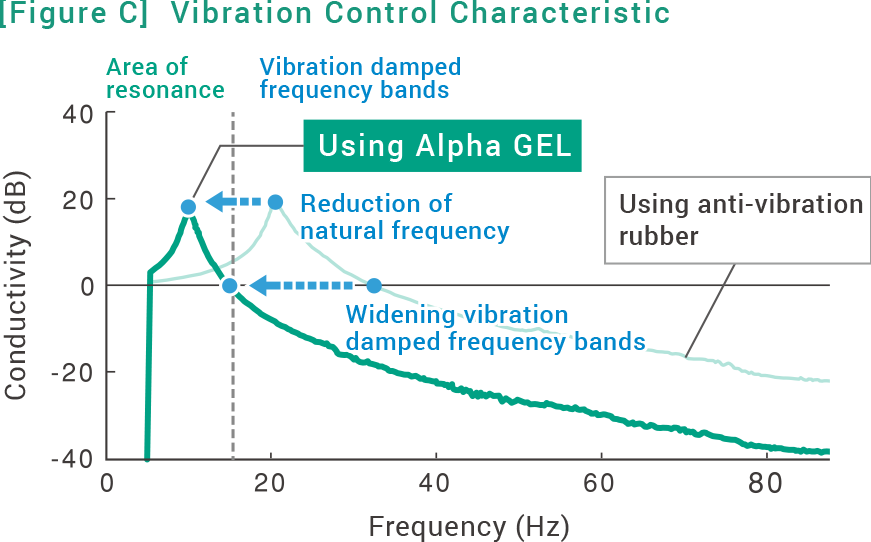

αGEL’s exceptional vibration damping functionality, combined with highly soft physical properties, makes it far superior to conventional rubber dampers. αGEL dampers can be used in both sensitive precision components and large-scale machinery for low to high frequency vibrations. αGEL offers unique solutions for all of your vibration damping needs.

Characteristics

- Feature.01

High Performance Damping - αGEL displays exceptional damping functionality (Loss Factor: tanδ). Its softness and pliability enables αGEL’s great vibration damping and vibration control performances.

- Feature.02

Low Frequencies / Low Loads - αGEL products offer solutions for both small, sensitive parts and large-scale heavy machinery. αGEL excels in protecting parts from low frequency vibrations and effectively reduces vibrations at a wide range of frequencies.

- Feature.03

Ultra Soft Silicone Material - αGEL is a silicone-based material that combines softness and durability with a very low compression set. It can be used at a wide range of temperatures(-40°C〜+200°C), resulting in unrivaled long-term reliability.

- Feature.04

Outstanding Durability - Compared to rubber or foam materials, αGEL shows superb durability against weathering, ozone, UV and various chemicals.

- Feature.05

Vibration Control

Design Know-how - We employ over 30 years of experience in the field of vibration control to offer you solutions with a customized size, hardness, and damping profile.

- Feature.06

Damping Simulation - Utilizing the Nonlinear Finite Element Analysis (FEA), we analyze and predict vibration.

- Feature.01

High Performance

Damping - αGEL displays exceptional damping functionality (Loss Factor: tanδ). Its softness and pliability give αGEL this great vibration damping and vibration control performances.

- Feature.02

Low Frequencies

Low Loads - αGEL products offer solutions for both small, sensitive parts and large-scale heavy machinery. αGEL excels in protecting parts from low frequency vibrations and effectively reduces vibrations at a wide range of frequencies.

- Feature.03

Ultra Soft

Silicone Material - αGEL is a silicone-based material that combines softness and durability with a very low compression set. It can be used at a wide range of temperatures(-40°C〜+200°C), resulting in unrivaled long-term reliability.

- Feature.04

Outstanding Durability - Compared to rubber or foam materials, αGEL shows superb durability against weathering, ozone, UV and various chemicals.

- Feature.05

Vibration Control

Design Know-how - We employ over 30 years of experience in the field of vibration control to offer you solutions with a customized size, hardness, and damping profile.

- Feature.06

Damping Simulation - Utilizing the Nonlinear Finite Element Analysis (FEA), we analyze and predict vibration.

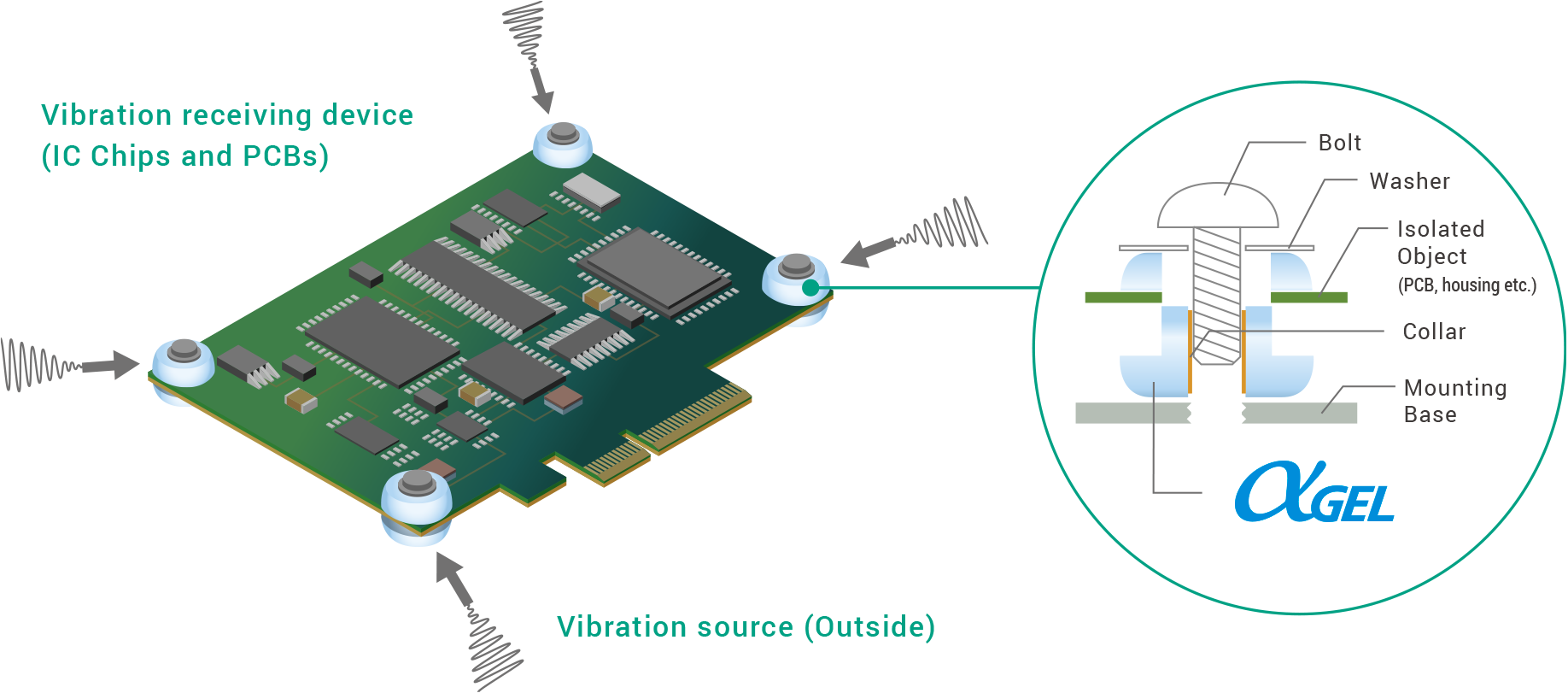

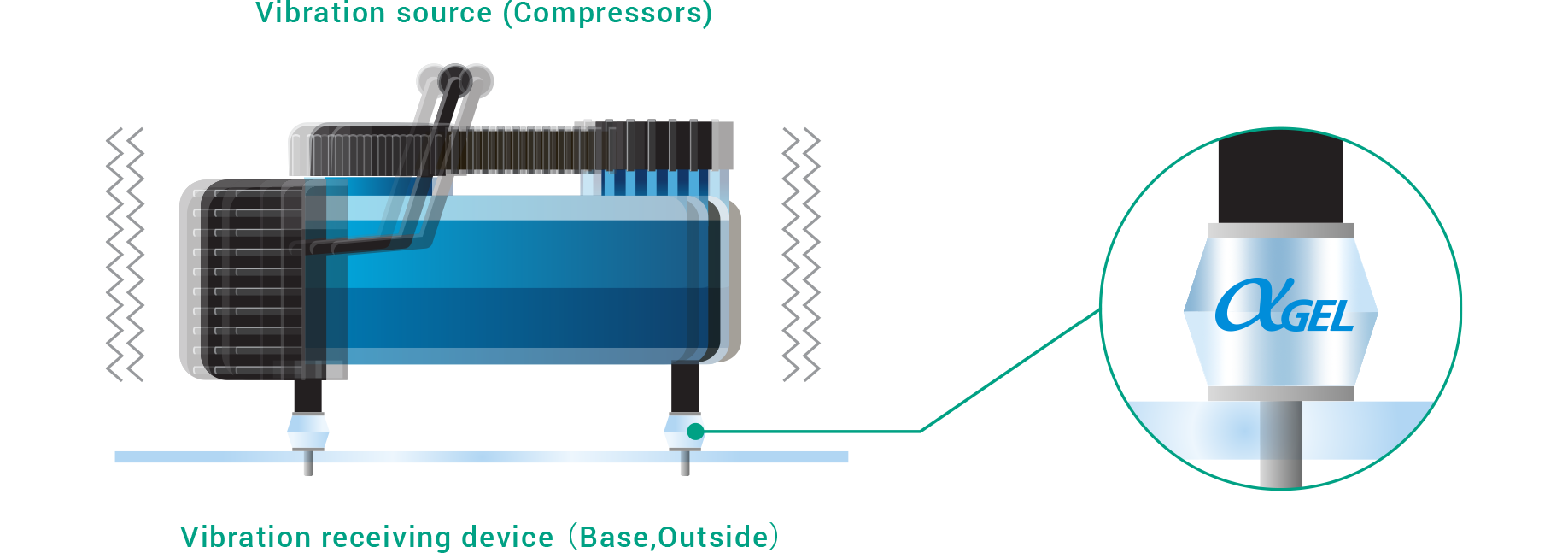

Application Example

By inserting αGEL between a vibration source and adjoining equipment/components, vibration transmission is reduced.

This protects the equipment/components and also reduces noise.

- Protection from outside vibration

- Protection from inside vibration

Mechanism

- Vibration damping

- Vibration damping is a method to reduce the number of vibration-associated malfunctions by mitigating vibration transmission. Taking vibration damping steps for motors, pumps, and other tremor-producing machinery reduces the extent of vibration transmitted to peripheral facilities, in turn cutting down vibration-related noise and vibration levels in surrounding areas and allowing for achieving a better environment. This approach is also effective in mitigating vibration coming from areas around vibration-sensitive machinery, but in such cases the approach is called vibration isolation to draw a distinction between vibration damping.

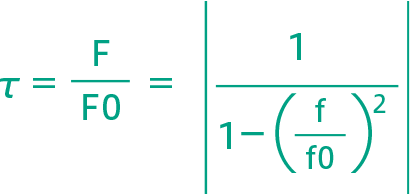

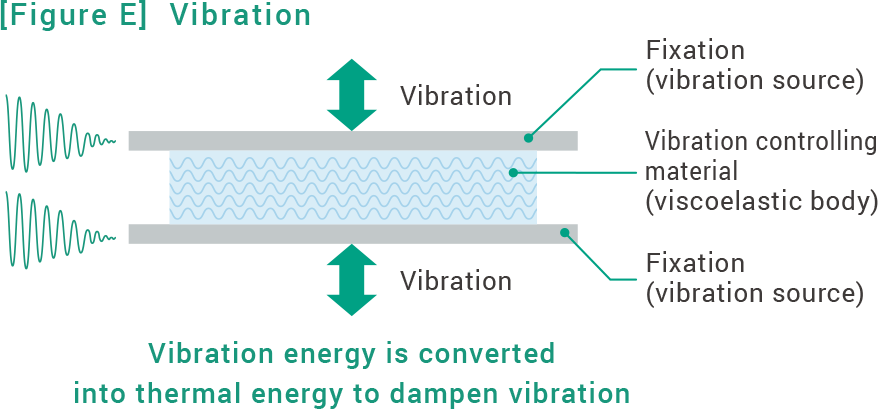

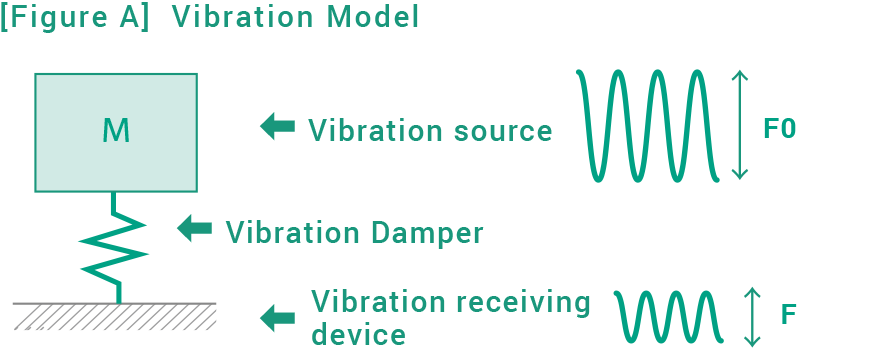

- The principle of vibration damping

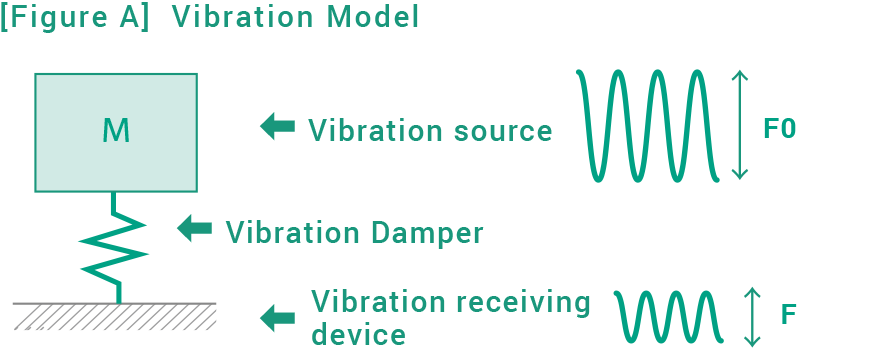

(vibration isolation) - Provided below is the vibration transmitted to peripheral facilities when the machinery generating vibration has an elastic-body-supported structure: (See Figure A)

-

- τ:Vibration conductivity

- F:Vibration level transmitted to peripheral facilities

- F0:Vibration level of vibration-generating machinery

- f: Vibration frequency of vibration-generating machinery

- f0:Natural frequency of elastically supported machinery

-

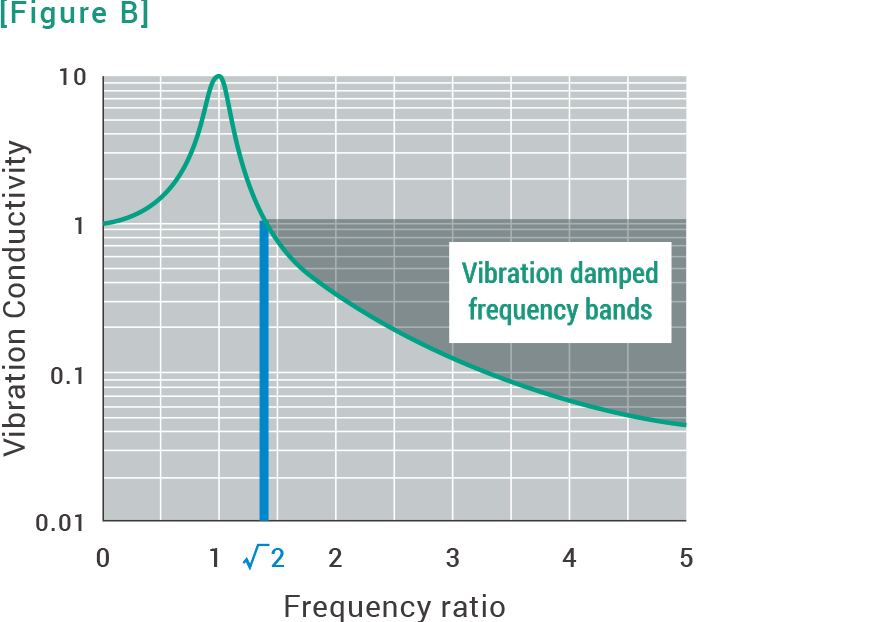

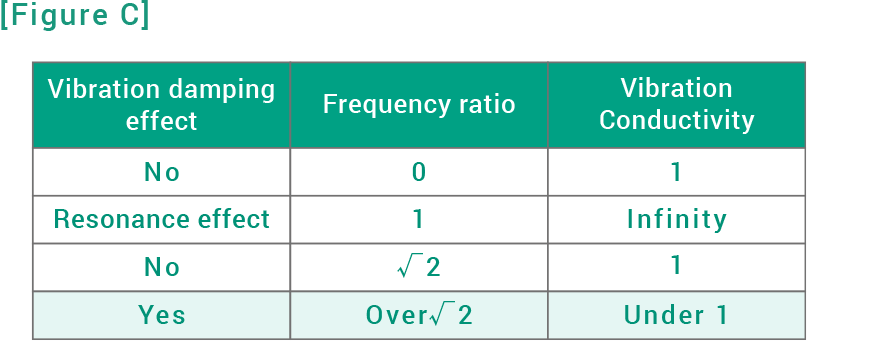

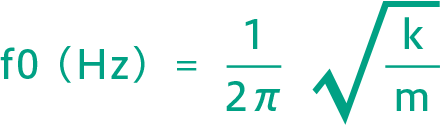

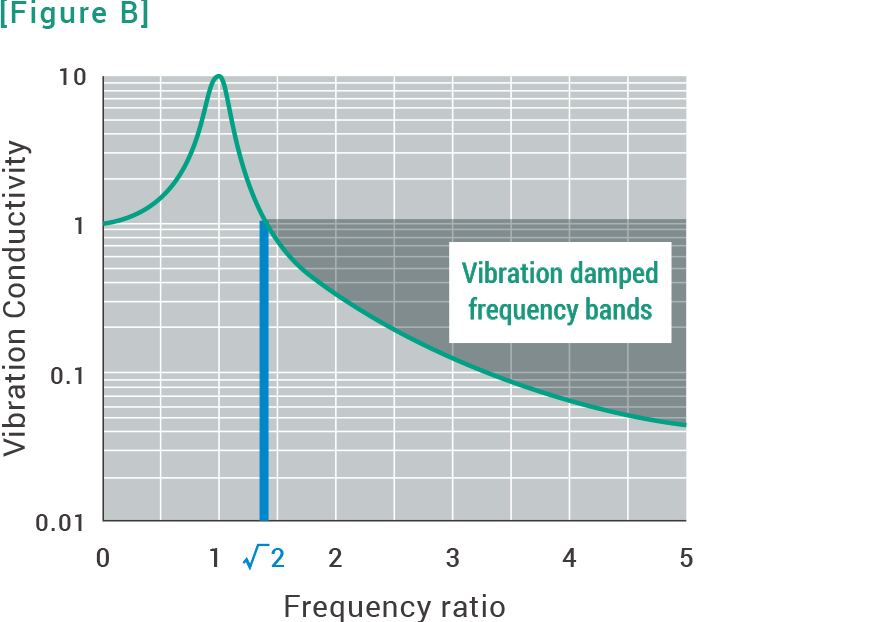

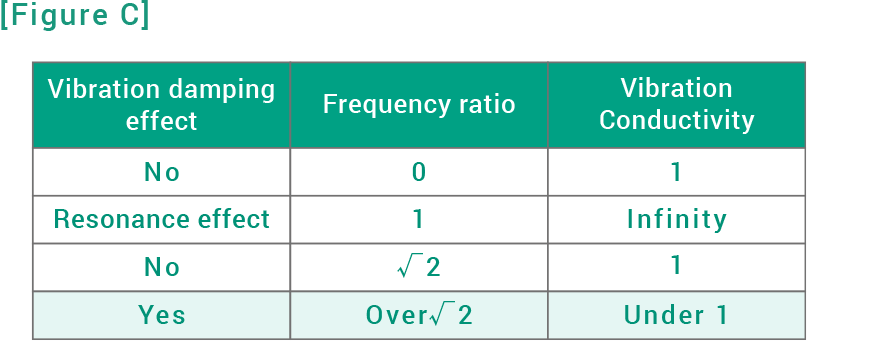

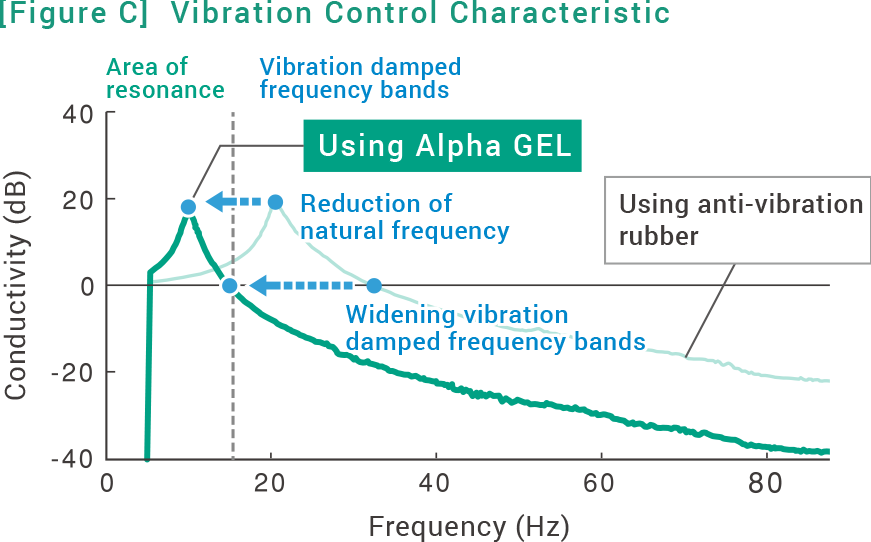

- The ratio of f and f0 (f/f0) is called the frequency ratio. Figure B shows the frequency ratio and conductivity. Figure C indicates the relationship between the frequency ratio and vibration damping effect. Bringing down the natural frequency f0 is important in dampening wider frequency bands. Natural frequency f0 (Hz) can be expressed by the equation below. Either softening the elastic support material or increasing the weight of the vibration-generating machinery allows for reducing f0. (See Figure D)

-

-

-

- k:Spring constant of elastic support material (N/m)

m:Weight of vibration-generating machinery (elastic support machinery) (kg) -

- Vibration control

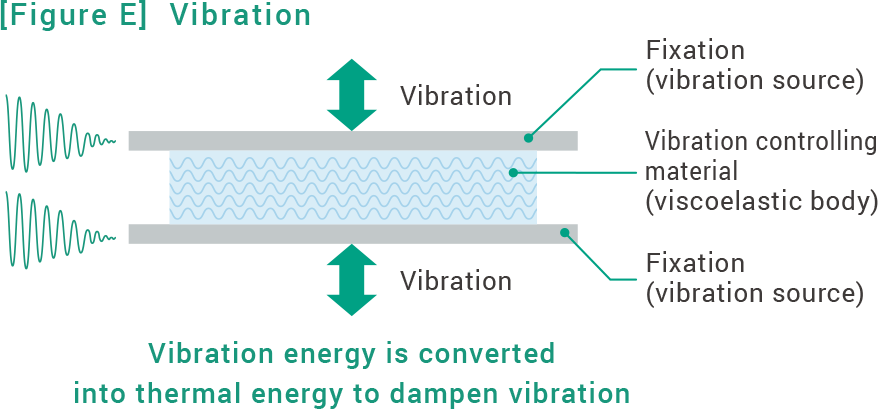

- Vibration damping (vibration isolation) is an effective approach to reducing vibration, but there may be no way to install vibration insulators in real usage conditions. In those situations, a technique called vibration control is harnessed to convert vibration energy into thermal energy, in turn suppressing vibration. Materials boasting a combination of damping properties and elasticity are called viscoelastic bodies, and the scale of damping properties regarding those bodies are expressed as a loss factor (tanδ). Materials with higher tanδ are considered to have better vibration control performance. (See Figure E)

-

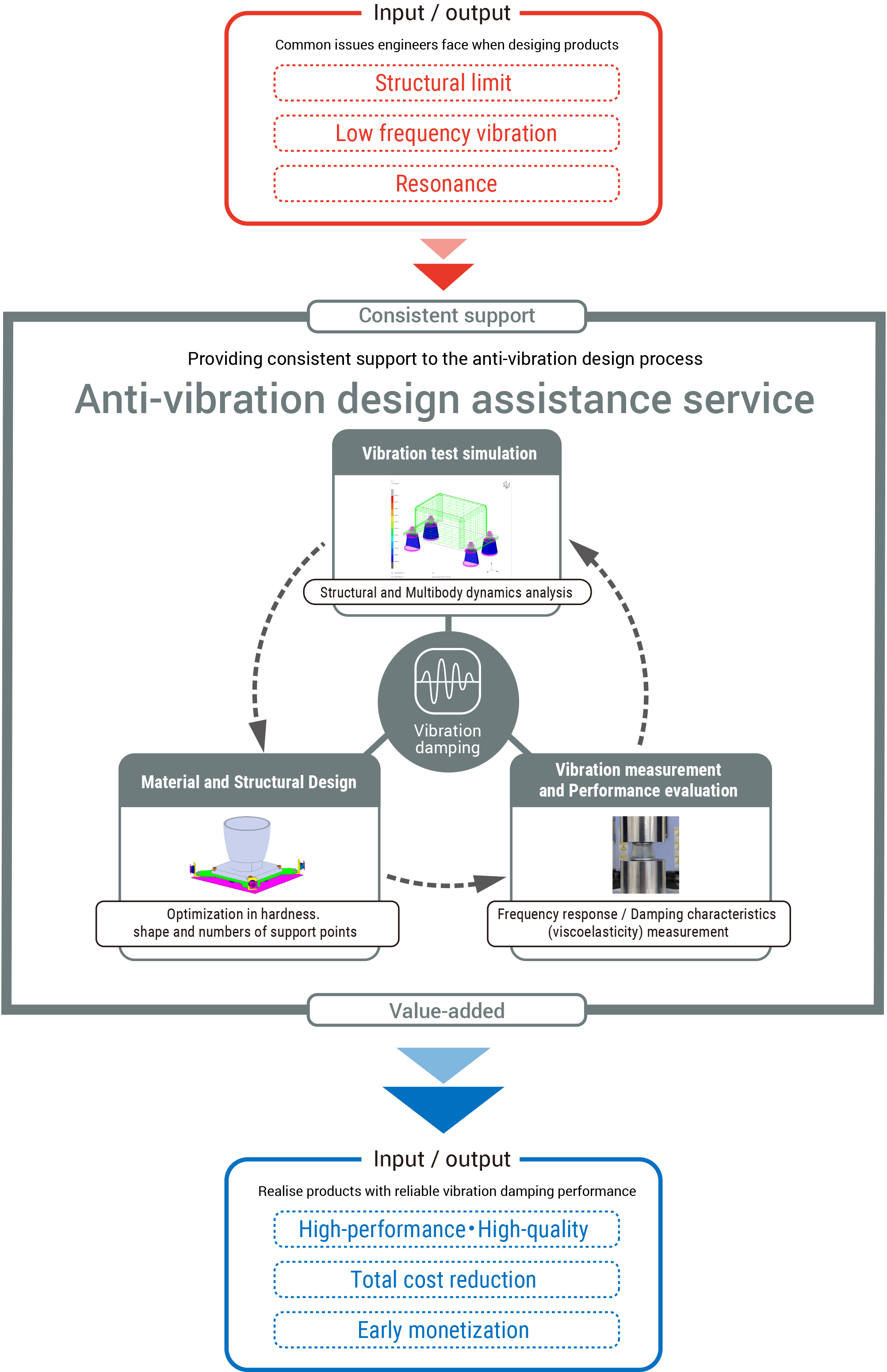

Anti-vibration design assistance service

- Providing the best-in-class solutions with the reliable design approach by the vibration isolation experts

- αGEL provides total support for the anti-vibration design process, which is indispensable for ensuring product quality and improving durability, with its know-how based on the knowledge and experience we have accumulated over the years, as well as its flexible conceptualization and technical capabilities to create new materials.We provide value-added solutions that contribute to the realization of high-performance, high-quality products and to the reduction of development costs.

Click here for more details

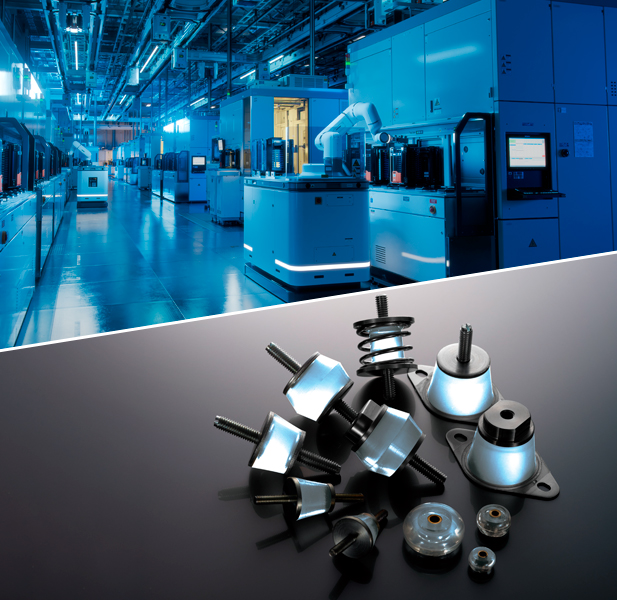

Applications

Products

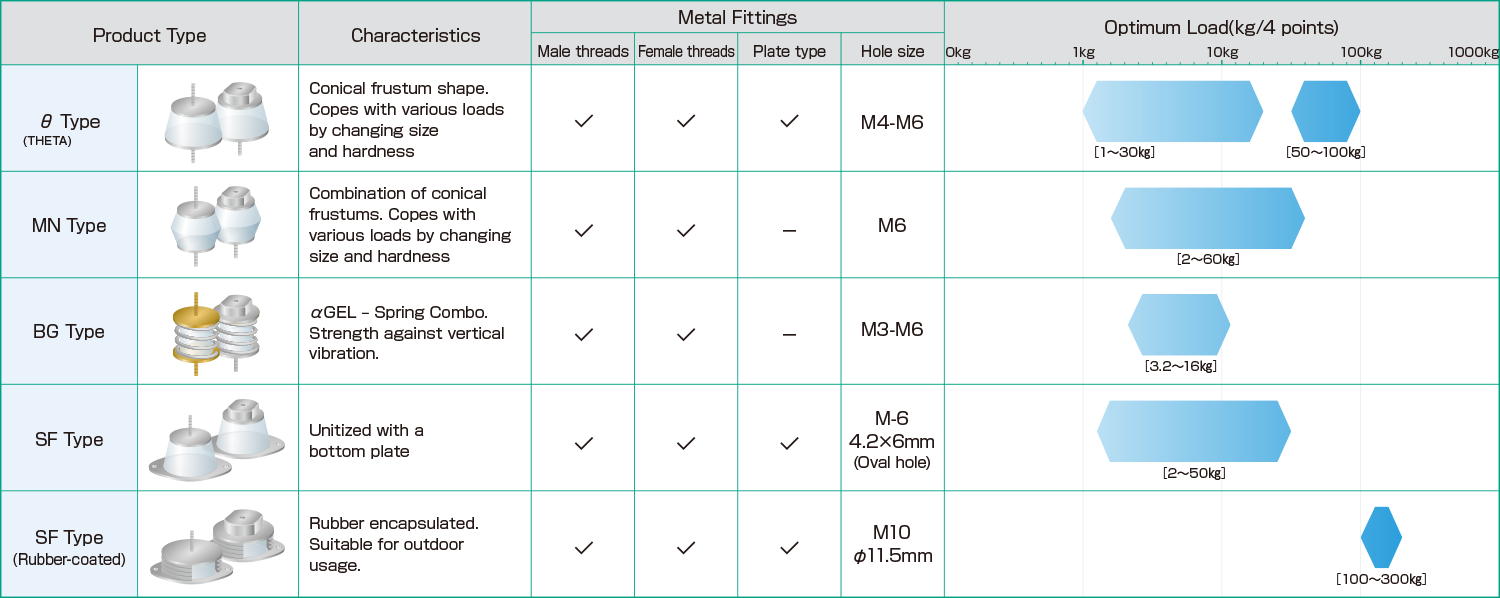

- Mounted Type

- These simply designed insulators support the product and effectively isolate vibrations.

Product Details

Product Details

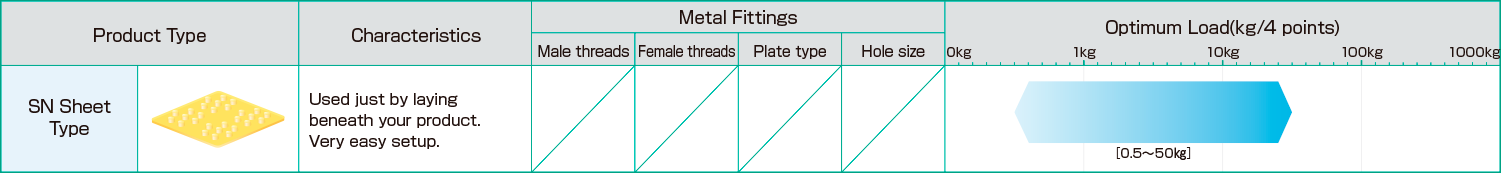

- Sheet-Type

- SN-Sheets are anti-vibration sheets that work by simply placing them under a product.

Product Details

Product Details

- UV Curing Gel (CIPD)

- Our CIPD (Cured-In-Place-Damping) silicone anti-vibration material is sold as a liquid that is cured in place with UV light.

| Product | Complex Modulus:G*(10Hz/Pa) |

|---|---|

| UV Curing Gel(CIPD) | 2,700~24,500 |

Product Details

Product Details

- Anti-vibration design assistance service

- As a development partner for anti-vibration design, we provide total support for vibration test simulation, material and structural design, vibration measurement, and performance evaluation.

| Overview | Detail |

|---|---|

| Vibration test simulation |

Structural and Multibody dynamics analysis |

| Material and Structural Design |

Optimization in hardness. shape and numbers of support points |

| Vibration measurement and Performance evaluation |

Frequency response / Damping characteristics (viscoelasticity) measurement |

Product Details

Product Details

Product Map

*Please swipe left or right to view table below.

-

Part No. Product

TypeOptimum Load

(kg/at 4 points)

MINOptimum Load

(kg/at 4 points)

MAXRecommended

Frequency Range

(Hz)Top Bottom Hole size Collar

(Inner

diameter)θ-A Mount Type

(Insulator)2 3.2 23〜 Male threads

Female threadsMale threads

PlateM4

φ4mm

(Hole)- θ-A-5 Mount Type

(Insulator)1 5 25〜 Male threads

Female threadsMale threads

PlateM4

φ4mm

(Hole)- θ-A-6 Mount Type

(Insulator)5 15 20〜 Male threads

Female threadsMale threads

PlateM4

φ4mm

(Hole)- θ-A-8 Mount Type

(Insulator)10 30 18〜 Male threads

Female threadsMale threads

PlateM4

φ4mm

(Hole)- θ-B Mount Type

(Insulator)1.6 2.4 18〜 Male threads

Female threadsMale threads

PlateM4

φ4mm

(Hole)- θ-C Mount Type

(Insulator)3.2 8 20〜 Male threads

Female threadsMale threads

PlateM6

φ6mm

(Hole)- θ-TW Mount Type

(Insulator)50 100 14〜 Male threads

Female threadsMale threads

PlateM6

2.6×8.2mm

(Oval hole)- MN-1 Mount Type

(Insulator)2 7 17〜 Male threads

Female threadsMale threads M6 - MN-2 Mount Type

(Insulator)3 9 17〜 Male threads

Female threadsMale threads M6 - MN-3 Mount Type

(Insulator)8 14 17〜 Male threads

Female threadsMale threads M6 - MN-5 Mount Type

(Insulator)14 22 16〜 Male threads

Female threadsMale threads M6 - MN-7 Mount Type

(Insulator)22 34 16〜 Male threads

Female threadsMale threads M6 - MN-10 Mount Type

(Insulator)34 50 16〜 Male threads

Female threadsMale threads M6 - MN-25 Mount Type

(Insulator)40 60 14〜 Male threads

Female threadsMale threads M6 - BG-7 Mount Type

(Insulator)3.2 6.4 14〜 Male threads

Female threadsMale threads M3 - BG-8 Mount Type

(Insulator)6 16 14〜 Male threads

Female threadsMale threads M6 - SF-0 Mount Type

(Insulator)2 9 16〜 Male threads

Female threadsPlate M6

4.2×6mm

(Oval hole)- SF-1 Mount Type

(Insulator)3 11 16〜 Male threads

Female threadsPlate M6

4.2×6mm

(Oval hole)- SF-2 Mount Type

(Insulator)5 13 22〜 Male threads

Female threadsPlate M6

4.2×6mm

(Oval hole)- SF-5 Mount Type

(Insulator)13 30 19〜 Male threads

Female threadsPlate M6

4.2×6mm

(Oval hole)- SF-10 Mount Type

(Insulator)30 50 17〜 Male threads

Female threadsPlate M6

4.2×6mm

(Oval hole)- SF-30 Mount Type

(Insulator)100 140 13〜 Male threads

Female threadsPlate M10

φ11.5mm

(Hole)- SF-50 Mount Type

(Insulator)120 300 15〜 Male threads

Female threadsPlate M10

φ11.5mm

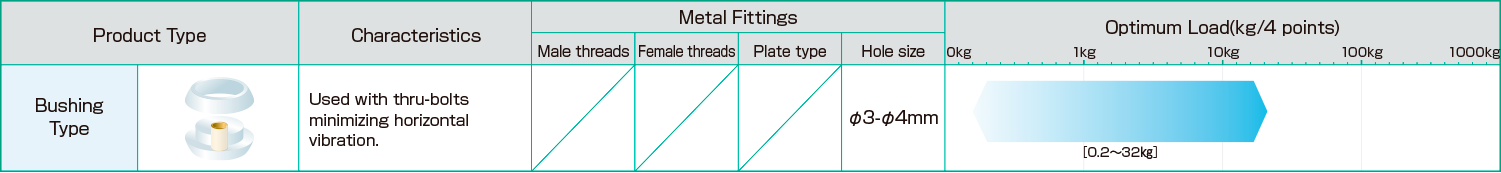

(Hole)- A-1 Bush Type

(GEL Bush)0.5 2.5 50〜 - - - φ3mm A-2 Bush Type

(GEL Bush)2.5 4 55〜 - - - φ3mm A-3 Bush Type

(GEL Bush)5 20 45〜 - - - φ3mm B-0.5 Bush Type

(GEL Bush)2 9 42〜 - - - φ4mm B-1 Bush Type

(GEL Bush)4 15 35〜 - - - φ4mm B-2 Bush Type

(GEL Bush)15 32 25〜 - - - φ4mm S Bush Type

(GEL Bush)0.2 0.75 60〜 - - - φ3mm S-5 Bush Type

(GEL Bush)0.6 1 53〜 - - - φ3mm S-6 Bush Type

(GEL Bush)3.5 4.5 43〜 - - - φ3mm S-8 Bush Type

(GEL Bush)10 14 39〜 - - - φ3mm SN-2

(Yellow)Sheet Type

(SN Sheet)0.5 2 38〜 - - - - SN-5

(Green)Sheet Type

(SN Sheet)2 5 40〜 - - - - SN-15

(Orange)Sheet Type

(SN Sheet)5 15 37〜 - - - - SN-50

(Blue)Sheet Type

(SN Sheet)15 50 30〜 - - - - Part No. θ-A θ-A-5 θ-A-6 θ-A-8 θ-B θ-C θ-TW MN-1 MN-2 MN-3 MN-5 MN-7 MN-10 MN-25 BG-7 BG-8 SF-0 SF-1 SF-2 SF-5 SF-10 SF-30 SF-50 A-1 A-2 A-3 B-0.5 B-1 B-2 S S-5 S-6 S-8 SN-2

(Yellow)SN-5

(Green)SN-15

(Orange)SN-50

(Blue)Product

TypeOptimum Load

(kg/at 4 points)

MINOptimum Load

(kg/at 4 points)

MAXRecommended

Frequency Range

(Hz)Top Bottom Hole size Collar

(Inner

diameter)Mount Type

(Insulator)2 3.2 23〜 Male threads

Female threadsMale threads

PlateM4

φ4mm

(Hole)- Mount Type

(Insulator)1 5 25〜 Male threads

Female threadsMale threads

PlateM4

φ4mm

(Hole)- Mount Type

(Insulator)5 15 20〜 Male threads

Female threadsMale threads

PlateM4

φ4mm

(Hole)- Mount Type

(Insulator)10 30 18〜 Male threads

Female threadsMale threads

PlateM4

φ4mm

(Hole)- Mount Type

(Insulator)1.6 2.4 18〜 Male threads

Female threadsMale threads

PlateM4

φ4mm

(Hole)- Mount Type

(Insulator)3.2 8 20〜 Male threads

Female threadsMale threads

PlateM6

φ6mm

(Hole)- Mount Type

(Insulator)50 100 14〜 Male threads

Female threadsMale threads

PlateM6

2.6×8.2mm

(Oval hole)- Mount Type

(Insulator)2 7 17〜 Male threads

Female threadsMale threads M6 - Mount Type

(Insulator)3 9 17〜 Male threads

Female threadsMale threads M6 - Mount Type

(Insulator)8 14 17〜 Male threads

Female threadsMale threads M6 - Mount Type

(Insulator)14 22 16〜 Male threads

Female threadsMale threads M6 - Mount Type

(Insulator)22 34 16〜 Male threads

Female threadsMale threads M6 - Mount Type

(Insulator)34 50 16〜 Male threads

Female threadsMale threads M6 - Mount Type

(Insulator)40 60 14〜 Male threads

Female threadsMale threads M6 - Mount Type

(Insulator)3.2 6.4 14〜 Male threads

Female threadsMale threads M3 - Mount Type

(Insulator)6 16 14〜 Male threads

Female threadsMale threads M6 - Mount Type

(Insulator)2 9 16〜 Male threads

Female threadsPlate M6

4.2×6mm

(Oval hole)- Mount Type

(Insulator)3 11 16〜 Male threads

Female threadsPlate M6

4.2×6mm

(Oval hole)- Mount Type

(Insulator)5 13 22〜 Male threads

Female threadsPlate M6

4.2×6mm

(Oval hole)- Mount Type

(Insulator)13 30 19〜 Male threads

Female threadsPlate M6

4.2×6mm

(Oval hole)- Mount Type

(Insulator)30 50 17〜 Male threads

Female threadsPlate M6

4.2×6mm

(Oval hole)- Mount Type

(Insulator)100 140 13〜 Male threads

Female threadsPlate M10

φ11.5mm

(Hole)- Mount Type

(Insulator)120 300 15〜 Male threads

Female threadsPlate M10

φ11.5mm

(Hole)- Bush Type

(GEL Bush)0.5 2.5 50〜 - - - φ3mm Bush Type

(GEL Bush)2.5 4 55〜 - - - φ3mm Bush Type

(GEL Bush)5 20 45〜 - - - φ3mm Bush Type

(GEL Bush)2 9 42〜 - - - φ4mm Bush Type

(GEL Bush)4 15 35〜 - - - φ4mm Bush Type

(GEL Bush)15 32 25〜 - - - φ4mm Bush Type

(GEL Bush)0.2 0.75 60〜 - - - φ3mm Bush Type

(GEL Bush)0.6 1 53〜 - - - φ3mm Bush Type

(GEL Bush)3.5 4.5 43〜 - - - φ3mm Bush Type

(GEL Bush)10 14 39〜 - - - φ3mm Sheet Type

(SN Sheet)0.5 2 38〜 - - - - Sheet Type

(SN Sheet)2 5 40〜 - - - - Sheet Type

(SN Sheet)5 15 37〜 - - - - Sheet Type

(SN Sheet)15 50 30〜 - - - - -

Part No. Product

TypeOptimum Load

(kg/at 4 points)

MINOptimum Load

(kg/at 4 points)

MAXRecommended

Frequency Range

(Hz)Top Bottom Hole size Collar

(Inner

diameter)S Bush Type

(GEL Bush)0.2 0.75 60〜 - - - φ3mm A-1 Bush Type

(GEL Bush)0.5 2.5 50〜 - - - φ3mm SN-2

(Yellow)Sheet Type

(SN Sheet)0.5 2 38〜 - - - - S-5 Bush Type

(GEL Bush)0.6 1 53〜 - - - φ3mm θ-A-5 Mount Type

(Insulator)1 5 25〜 Male threads

Female threadsMale threads

PlateM4

φ4mm

(Hole)- θ-B Mount Type

(Insulator)1.6 2.4 18〜 Male threads

Female threadsMale threads

PlateM4

φ4mm

(Hole)- θ-A Mount Type

(Insulator)2 3.2 23〜 Male threads

Female threadsMale threads

PlateM4

φ4mm

(Hole)- MN-1 Mount Type

(Insulator)2 7 17〜 Male threads

Female threadsMale threads M6 - SF-0 Mount Type

(Insulator)2 9 16〜 Male threads

Female threadsPlate M6

4.2×6mm

(Oval hole)- B-0.5 Bush Type

(GEL Bush)2 9 42〜 - - - φ4mm SN-5

(Green)Sheet Type

(SN Sheet)2 5 40〜 - - - - A-2 Bush Type

(GEL Bush)2.5 4 55〜 - - - φ3mm MN-2 Mount Type

(Insulator)3 9 17〜 Male threads

Female threadsMale threads M6 - SF-1 Mount Type

(Insulator)3 11 16〜 Male threads

Female threadsPlate M6

4.2×6mm

(Oval hole)- θ-C Mount Type

(Insulator)3.2 8 20〜 Male threads

Female threadsMale threads

PlateM6

φ6mm

(Hole)- BG-7 Mount Type

(Insulator)3.2 6.4 14〜 Male threads

Female threadsMale threads M3 - S-6 Bush Type

(GEL Bush)3.5 4.5 43〜 - - - φ3mm B-1 Bush Type

(GEL Bush)4 15 35〜 - - - φ4mm θ-A-6 Mount Type

(Insulator)5 15 20〜 Male threads

Female threadsMale threads

PlateM4

φ4mm

(Hole)- SF-2 Mount Type

(Insulator)5 13 22〜 Male threads

Female threadsPlate M6

4.2×6mm

(Oval hole)- A-3 Bush Type

(GEL Bush)5 20 45〜 - - - φ3mm SN-15

(Orange)Sheet Type

(SN Sheet)5 15 37〜 - - - - BG-8 Mount Type

(Insulator)6 16 14〜 Male threads

Female threadsMale threads M6 - MN-3 Mount Type

(Insulator)8 14 17〜 Male threads

Female threadsMale threads M6 - θ-A-8 Mount Type

(Insulator)10 30 18〜 Male threads

Female threadsMale threads

PlateM4

φ4mm

(Hole)- S-8 Bush Type

(GEL Bush)10 14 39〜 - - - φ3mm SF-5 Mount Type

(Insulator)13 30 19〜 Male threads

Female threadsPlate M6

4.2×6mm

(Oval hole)- MN-5 Mount Type

(Insulator)14 22 16〜 Male threads

Female threadsMale threads M6 - B-2 Bush Type

(GEL Bush)15 32 25〜 - - - φ4mm SN-50

(Blue)Sheet Type

(SN Sheet)15 50 30〜 - - - - MN-7 Mount Type

(Insulator)22 34 16〜 Male threads

Female threadsMale threads M6 - SF-10 Mount Type

(Insulator)30 50 17〜 Male threads

Female threadsPlate M6

4.2×6mm

(Oval hole)- MN-10 Mount Type

(Insulator)34 50 16〜 Male threads

Female threadsMale threads M6 - MN-25 Mount Type

(Insulator)40 60 14〜 Male threads

Female threadsMale threads M6 - θ-TW Mount Type

(Insulator)50 100 14〜 Male threads

Female threadsMale threads

PlateM6

2.6×8.2mm

(Oval hole)- SF-30 Mount Type

(Insulator)100 140 13〜 Male threads

Female threadsPlate M10

φ11.5mm

(Hole)- SF-50 Mount Type

(Insulator)120 300 15〜 Male threads

Female threadsPlate M10

φ11.5mm

(Hole)- Part No. S A-1 SN-2

(Yellow)S-5 θ-A-5 θ-B θ-A MN-1 SF-0 B-0.5 SN-5

(Green)A-2 MN-2 SF-1 θ-C BG-7 S-6 B-1 θ-A-6 SF-2 A-3 SN-15

(Orange)BG-8 MN-3 θ-A-8 S-8 SF-5 MN-5 B-2 SN-50

(Blue)MN-7 SF-10 MN-10 MN-25 θ-TW SF-30 SF-50 Product

TypeOptimum Load

(kg/at 4 points)

MINOptimum Load

(kg/at 4 points)

MAXRecommended

Frequency Range

(Hz)Top Bottom Hole size Collar

(Inner

diameter)Bush Type

(GEL Bush)0.2 0.75 60〜 - - - φ3mm Bush Type

(GEL Bush)0.5 2.5 50〜 - - - φ3mm Sheet Type

(SN Sheet)0.5 2 38〜 - - - - Bush Type

(GEL Bush)0.6 1 53〜 - - - φ3mm Mount Type

(Insulator)1 5 25〜 Male threads

Female threadsMale threads

PlateM4

φ4mm

(Hole)- Mount Type

(Insulator)1.6 2.4 18〜 Male threads

Female threadsMale threads

PlateM4

φ4mm

(Hole)- Mount Type

(Insulator)2 3.2 23〜 Male threads

Female threadsMale threads

PlateM4

φ4mm

(Hole)- Mount Type

(Insulator)2 7 17〜 Male threads

Female threadsMale threads M6 - Mount Type

(Insulator)2 9 16〜 Male threads

Female threadsPlate M6

4.2×6mm

(Oval hole)- Bush Type

(GEL Bush)2 9 42〜 - - - φ4mm Sheet Type

(SN Sheet)2 5 40〜 - - - - Bush Type

(GEL Bush)2.5 4 55〜 - - - φ3mm Mount Type

(Insulator)3 9 17〜 Male threads

Female threadsMale threads M6 - Mount Type

(Insulator)3 11 16〜 Male threads

Female threadsPlate M6

4.2×6mm

(Oval hole)- Mount Type

(Insulator)3.2 8 20〜 Male threads

Female threadsMale threads

PlateM6

φ6mm

(Hole)- Mount Type

(Insulator)3.2 6.4 14〜 Male threads

Female threadsMale threads M3 - Bush Type

(GEL Bush)3.5 4.5 43〜 - - - φ3mm Bush Type

(GEL Bush)4 15 35〜 - - - φ4mm Mount Type

(Insulator)5 15 20〜 Male threads

Female threadsMale threads

PlateM4

φ4mm

(Hole)- Mount Type

(Insulator)5 13 22〜 Male threads

Female threadsPlate M6

4.2×6mm

(Oval hole)- Bush Type

(GEL Bush)5 20 45〜 - - - φ3mm Sheet Type

(SN Sheet)5 15 37〜 - - - - Mount Type

(Insulator)6 16 14〜 Male threads

Female threadsMale threads M6 - Mount Type

(Insulator)8 14 17〜 Male threads

Female threadsMale threads M6 - Mount Type

(Insulator)10 30 18〜 Male threads

Female threadsMale threads

PlateM4

φ4mm

(Hole)- Bush Type

(GEL Bush)10 14 39〜 - - - φ3mm Mount Type

(Insulator)13 30 19〜 Male threads

Female threadsPlate M6

4.2×6mm

(Oval hole)- Mount Type

(Insulator)14 22 16〜 Male threads

Female threadsMale threads M6 - Bush Type

(GEL Bush)15 32 25〜 - - - φ4mm Sheet Type

(SN Sheet)15 50 30〜 - - - - Mount Type

(Insulator)22 34 16〜 Male threads

Female threadsMale threads M6 - Mount Type

(Insulator)30 50 17〜 Male threads

Female threadsPlate M6

4.2×6mm

(Oval hole)- Mount Type

(Insulator)34 50 16〜 Male threads

Female threadsMale threads M6 - Mount Type

(Insulator)40 60 14〜 Male threads

Female threadsMale threads M6 - Mount Type

(Insulator)50 100 14〜 Male threads

Female threadsMale threads

PlateM6

2.6×8.2mm

(Oval hole)- Mount Type

(Insulator)100 140 13〜 Male threads

Female threadsPlate M10

φ11.5mm

(Hole)- Mount Type

(Insulator)120 300 15〜 Male threads

Female threadsPlate M10

φ11.5mm

(Hole)-