- TOP

- αGEL Products

- Vibration Damping/UV Curing Gel(CIPD)

αGEL Products

UV Curing Gel(CIPD)

Our CIPD (Cured-In-Place-Damping) silicone anti-vibration material is sold as a liquid that is cured in place with UV light. By fine-tuning softness and damping functionality (Loss Factor tanδ, etc.), our CIPD shows peerless vibration control functionality in highly sensitive precision components.

- Characteristics

- ●Tunable damping characteristics (e.g. Loss Factor tanδ) for many applications.

- ●UV Curing Gel boasts a very low compression set, resulting in long-lasting, stable performance.

- ●Thanks to the power of UV curing, this GEL hardens more quickly than standard moisture curing materials, reducing process time.

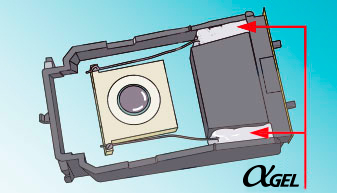

- ●Often used as damping material in optical pick-ups.

- Application Example

- UV Curing GEL is often used as damping material in optical pick up devices. UV Curing GEL comes in liquid state.

- Technical Information

-

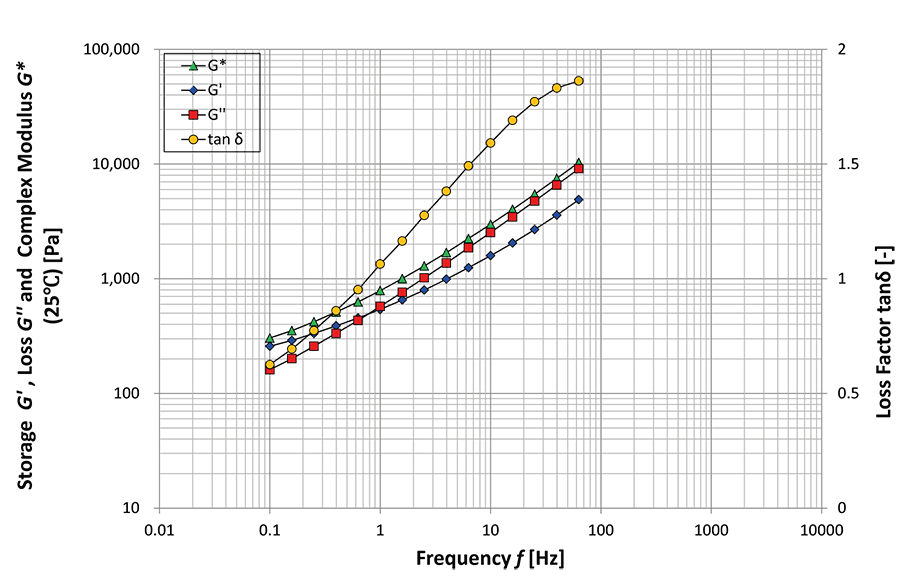

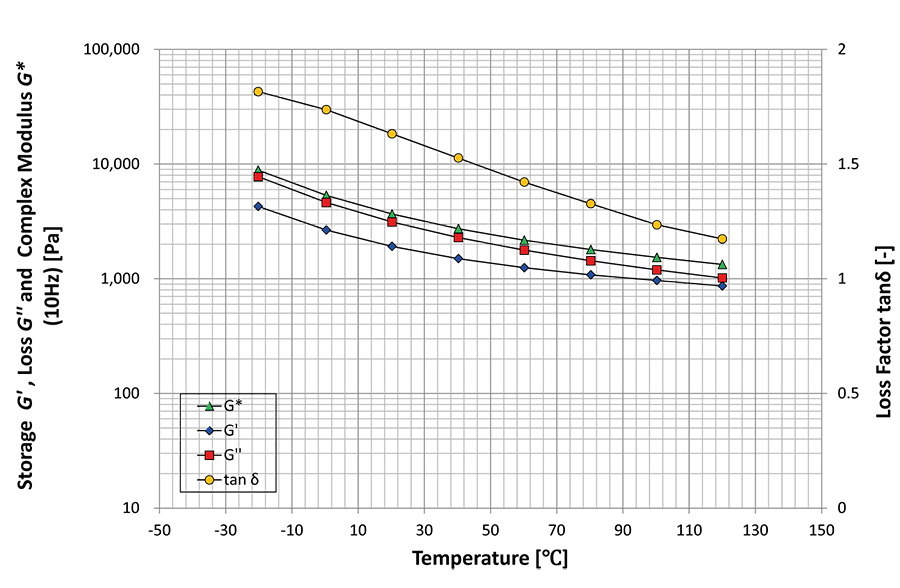

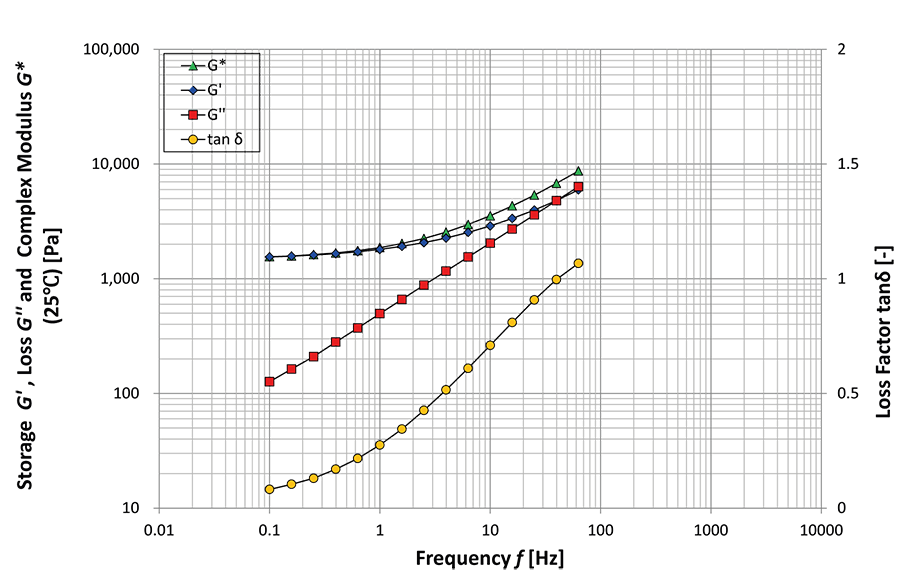

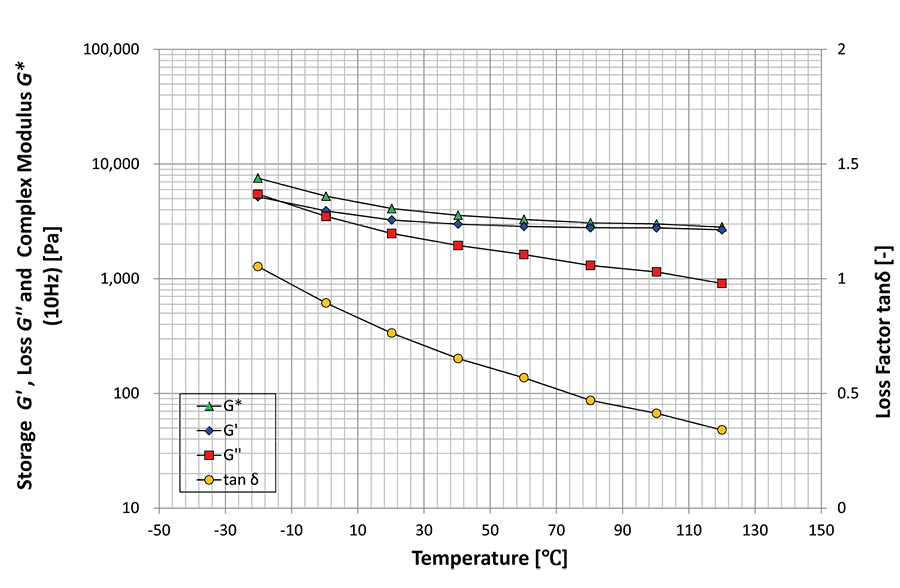

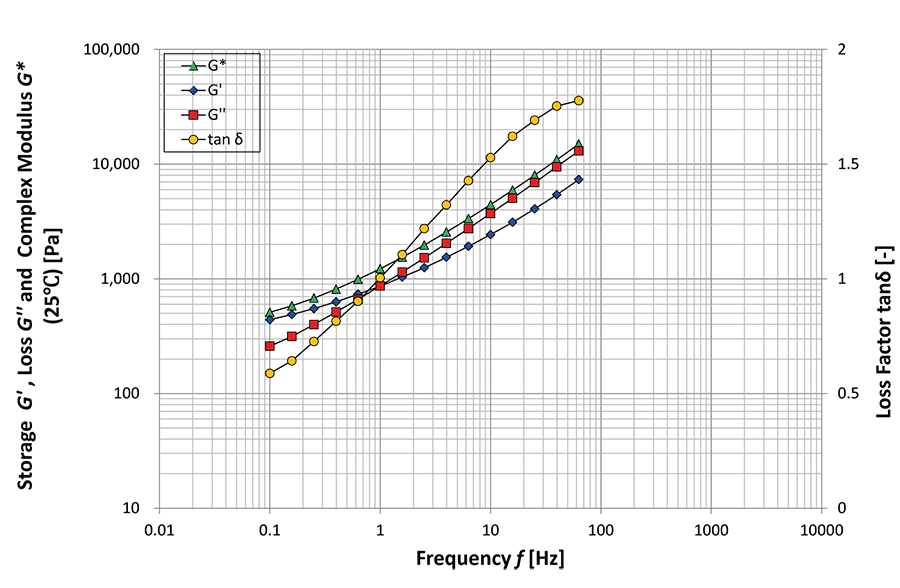

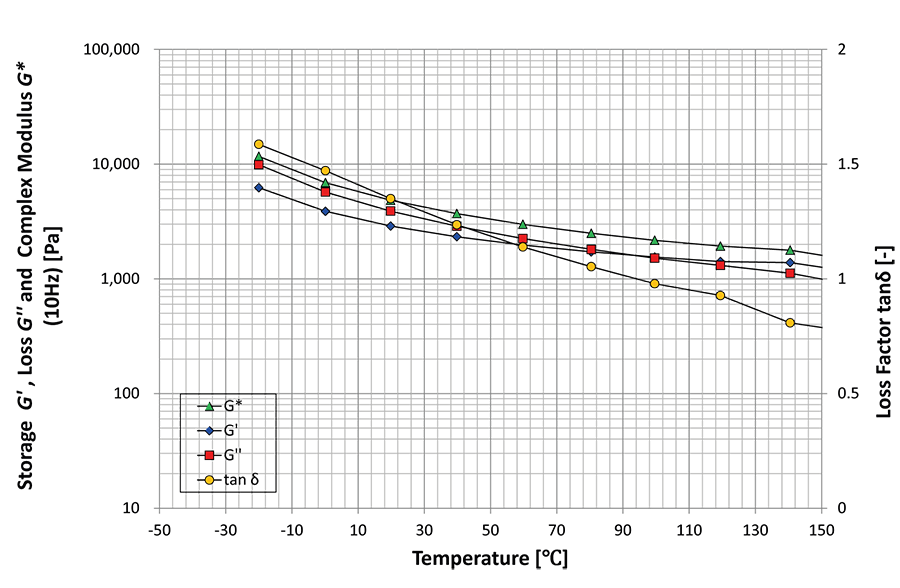

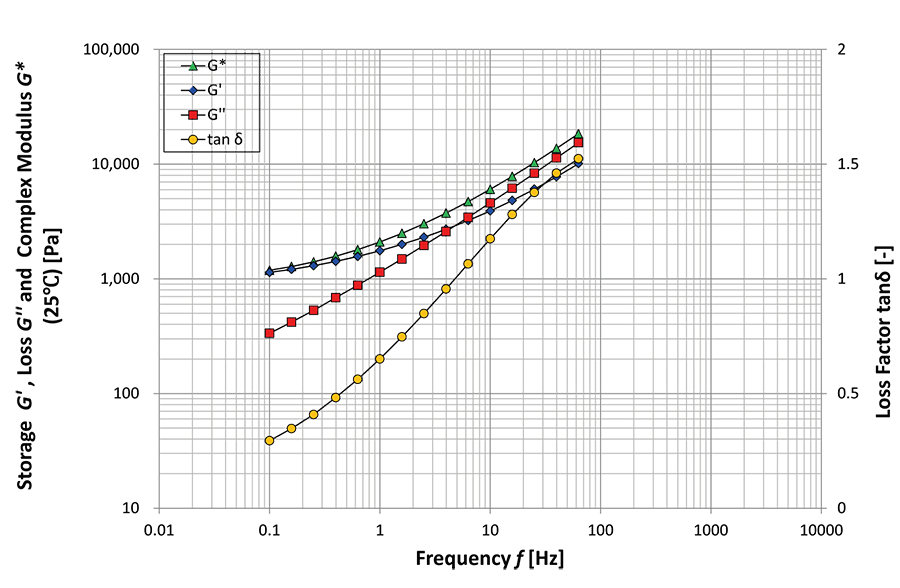

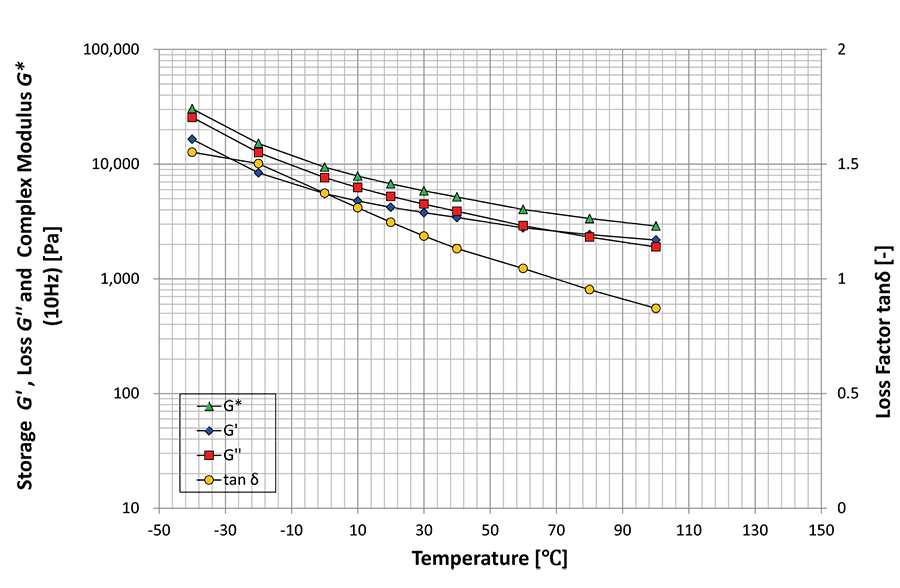

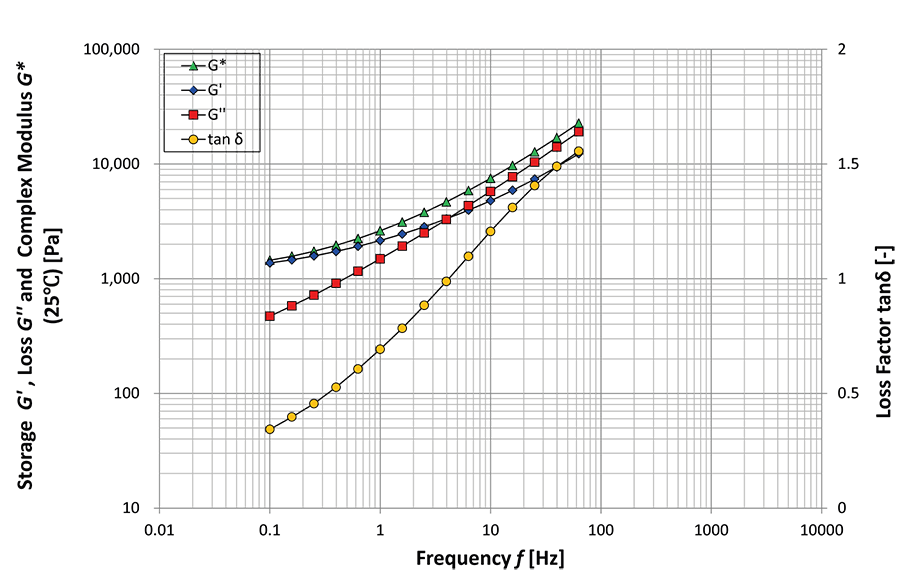

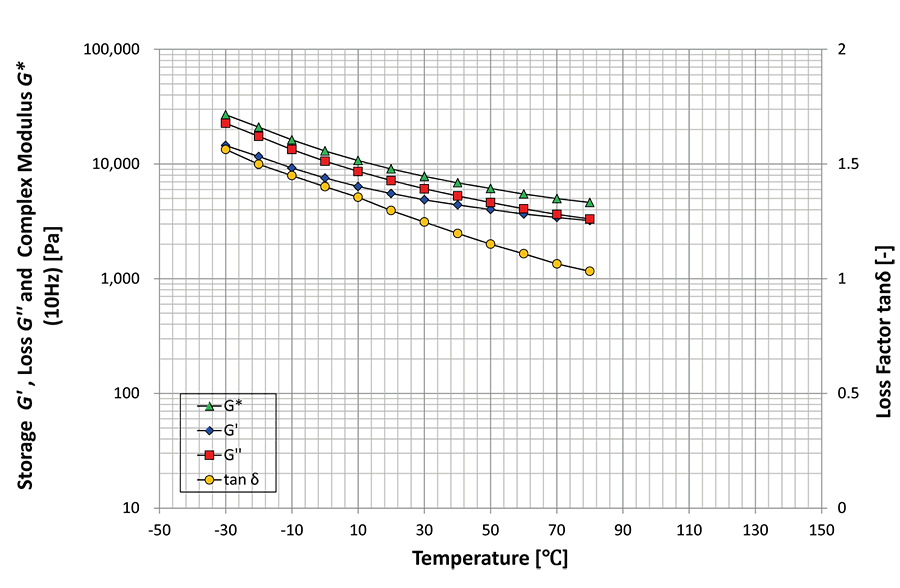

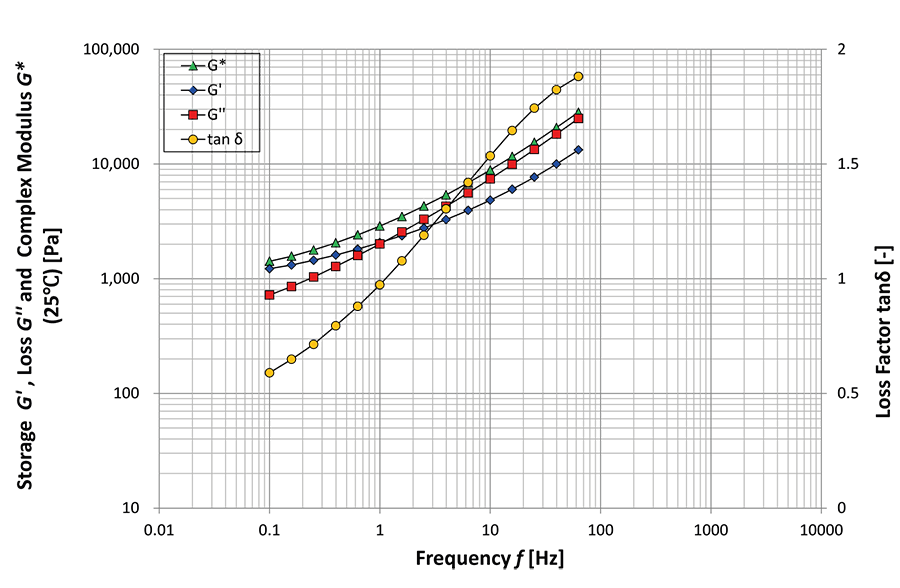

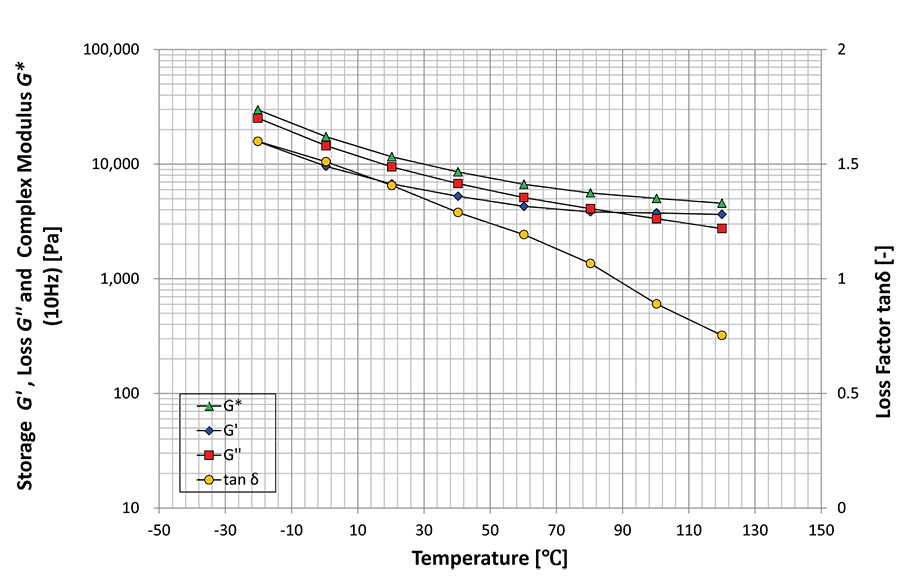

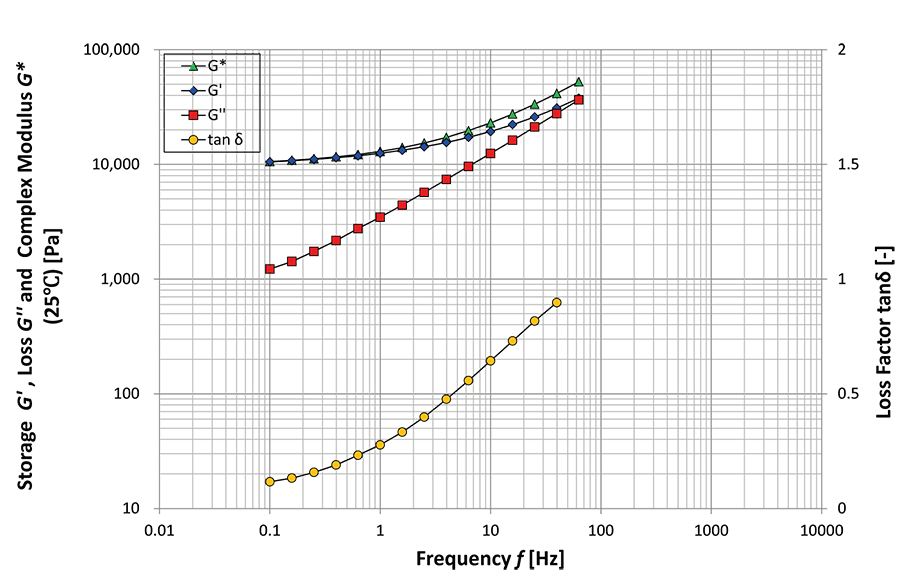

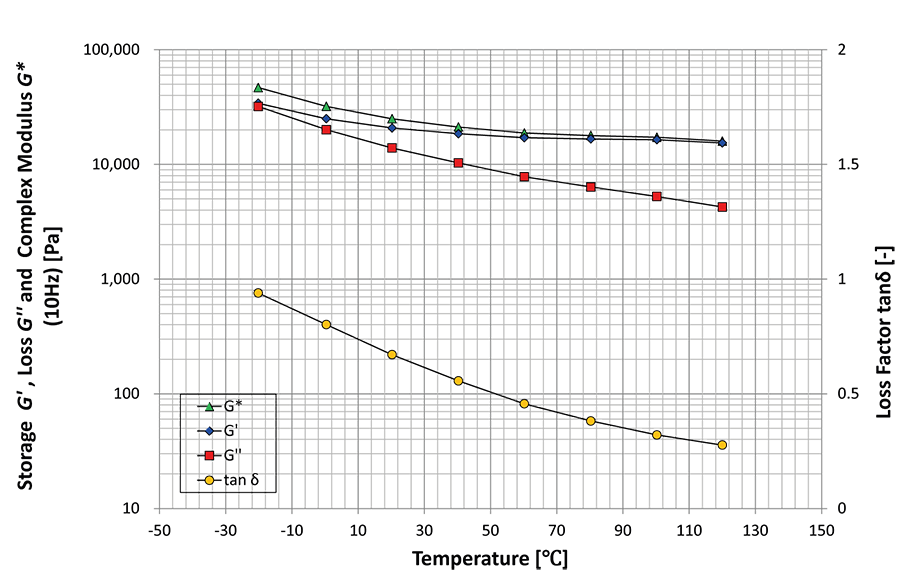

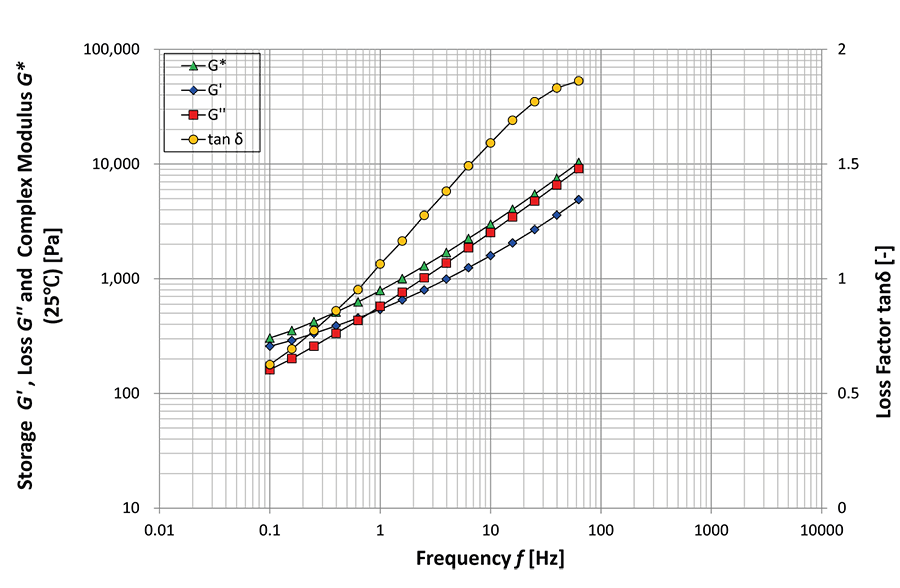

[Dynamic viscoelasticity (Silicone GEL B Frequency response)]

- Packaging

-

Product is supplied in a

light-proof bottle.- ●Easy handling and transport.

- ●May be transferred into syringes or other containers for customized application.

Product Details

[Properties of UV Curing Gel(CIPD)]

| Product | Complex Modulus:G* (10Hz/Pa) |

Loss Factor: tanδ |

Initial Viscosity (Rotary Speed) |

Appearance |

|---|---|---|---|---|

| Silicone GEL B | 2,700 Pa | 1.9 | 6 Pa・s (40 rpm) | Opaque White |

| Silicone GEL C | 3,500 Pa | 0.7 | 3 Pa・s (40 rpm) | Transparent |

| Silicone GEL E | 4,300 Pa | 1.5 | 7 Pa・s (40 rpm) | Opaque White |

| Silicone GEL G | 6,800 Pa | 1.1 | 9 Pa・s (40 rpm) | Opaque White |

| Silicone GEL H | 7,500 Pa | 1.2 | 15 Pa・s (10 rpm) | Opaque White |

| Silicone GEL J | 8,200 Pa | 1.6 | 50 Pa・s (10 rpm) | Opaque Pink |

| Silicone GEL L | 24,500 Pa | 0.8 | 28 Pa・s (10 rpm) | Opaque White |

※Silicone oil may bleed depending upon conditions.

※Low molecular siloxane is included in this product which basically composed of silicone.

※Above data are measured data, not guaranteed specifications.

Dynamic viscoelasticity data

Product Map

| Product | Complex Modulus:G* (10Hz/Pa) |

Loss Factor: tanδ |

|---|---|---|

| Silicone GEL B | 2,700 | 1.9 |

| Silicone GEL C | 3,500 | 0.7 |

| Silicone GEL E | 4,300 | 1.5 |

| Silicone GEL G | 6,800 | 1.1 |

| Silicone GEL H | 7,500 | 1.2 |

| Silicone GEL J | 8,200 | 1.6 |

| Silicone GEL L | 24,500 | 0.8 |

Notes

・Requires dispensing equipment and a UV light source for curing.

・A UV lamp intensity of 100 - 300 mW/cm2 applied for 20 - 30 seconds will cure the product to a stable hardness.

・As sunlight and fluorescent lights contain UV light, any exposure to these light sources will start the curing reaction. Avoid exposure to sunlight, and apply a UV filter to any fluorescent lights in the workspace.

- Customization

- We also develop custom products to meet our customers’ individual needs. Contact us today!