- TOP

- αGEL Products

- Water & Dust Proofing/Gasket(CIPG)

αGEL Products

Gasket(CIPG)

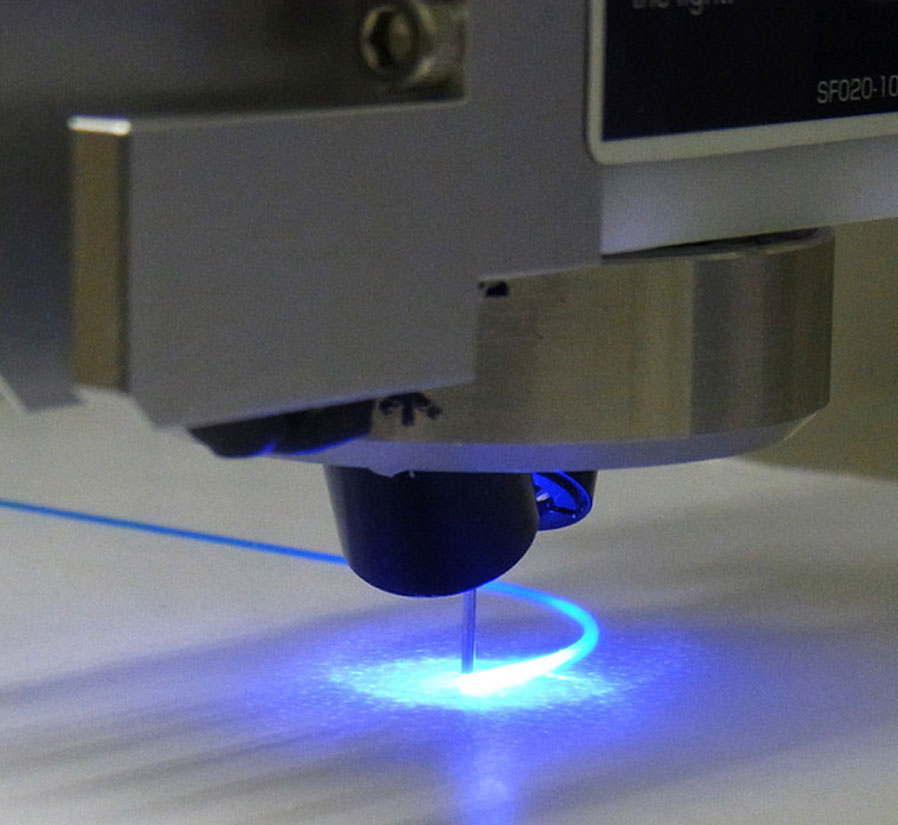

Alpha GEL Cured-In-Place Gasket (CIPG) is applied with an automated system directed by 3D plotting software and cured in place with UV light. Its elasticity, compressibility, and ability to follow part warpage impart Alpha GEL CIPG with its superior water and dust proofing functionality.

- Characteristics

- ●Alpha GEL CIPG is designed with a perfect balance of material properties both before and after UV curing.

- ●Thanks to the power of UV curing, Alpha GEL CIPG hardens more quickly than standard moisture curing, reducing process time.

- ●Automated application eliminates the need for injection molds and assembly processes required by traditional rubber gaskets. This lowers production costs and improves efficiency.

- Application Example

- CIPG (Cured-In Place Gasket) technology is a state-of-the-art gasket solution using Alpha GEL. It offers excellent waterproofing and dustproofing for smartphones and tables.

- Technical Information

-

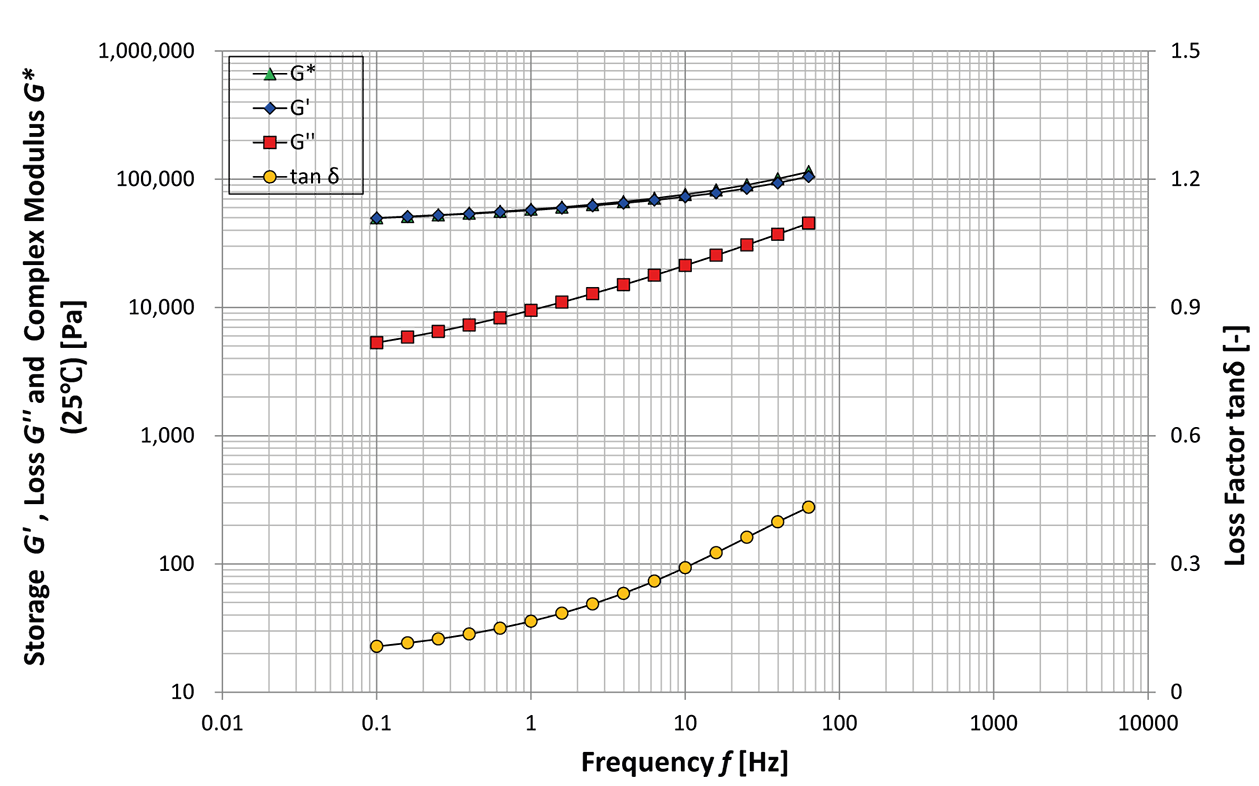

[Dynamic viscoelasticity (TUQ75K (silicone) frequency response)]

- Product・Packaging

-

Product is supplied in a

light-proof bottle.- ●Easy handling and transport.

- ●May be transferred into syringes or other containers for customized application.

Product Details

*Please swipe left or right to view table below.

[Properties of Gasket(CIPG)]

| Material | unit | TUQ75K | ||

|---|---|---|---|---|

| Silicone | ||||

| Before UV Curing | Appearance | Blue | ||

| Initial Viscosity(1[s-1]) | Pa・s | 370 | ||

| After UV Curing | Appearance | Blue | ||

| Hardness(Durometer A) | 10 | |||

| Hardness(Durometer E) | 30 | |||

| Complex Modulus(10Hz G*) | Pa | 75,000 | ||

| Loss Factor(tanδ) | 0.3 | |||

| Specific Gravity | g/cm3 | 1.05 | ||

| Low Molecular Weight Siloxane Level | ppm | Less than 700 | ||

| Curing Conditions | Irradiation | mW/cm2 | 50~200 | |

| Wave Length | nm | 280~365 | ||

| UV Curing Amount(Conversion 365nm) | mJ/cm2 | More than 2,000 | ||

| Others | Compression Ratio | % | 25~50 | |

| Water-proof | IP | Higher than IPX5/IPX7 | ||

| Storage | Dark Place, 1~10℃ | |||

| Packaging | Opaque Syringe | |||

| Material | |

|---|---|

| Before UV Curing | Appearance |

| Initial Viscosity(1[s-1]) | |

| After UV Curing | Appearance |

| Hardness (Durometer A) |

|

| Hardness (Durometer E) |

|

| Complex Modulus(10Hz G*) | |

| Loss Factor (tanδ) |

|

| Specific Gravity | |

| Low Molecular Weight Siloxane Level |

|

| Curing Conditions | Irradiation |

| Wave Length | |

| UV Curing Amount (Conversion 365nm) |

|

| Others | Compression Ratio |

| Water-proof | |

| Storage | |

| Packaging | |

| unit | TUQ75K | |

|---|---|---|

| Silicone | ||

| Blue | ||

| Pa・s | 370 | |

| Blue | ||

| 10 | ||

| 30 | ||

| Pa | 75,000 | |

| 0.3 | ||

| g/cm3 | 1.05 | |

| ppm | Less than 700 | |

| mW/cm2 | 50~200 | |

| nm | 280~365 | |

| mJ/cm2 | More than 2,000 | |

| % | 25~50 | |

| IP | IPX5 / IPX7以上 | |

| Dark Place, 1~10℃ | ||

| Opaque Syringe | ||

※Silicone oil may bleed depending upon conditions.

※Low molecular siloxane is included in this product which basically composed of silicone.

※Above data are measured data, not guaranteed specifications.

Product Map

| Product | Material | Complex Modulus:G* (10Hz/Pa) |

Loss Factor: tanδ |

|---|---|---|---|

| TUQ75K | Silicone | 75,000 | 0.3 |

Notes

- ・Due to UV-irradiation in sunlight and fluorescent light, any light exposure will cause the curing reaction of this product to start. Please avoid exposure to outside light and use fluorescent lamps with a UV filter.

- ・Please refer to the following curing conditions.

-

Curing Conditions Irradiation mW/cm² 50 〜 200 Wave Length nm 280〜365 UV Curing Amount

(Conversion 365nm)mJ/cm² More than 2,000 - ・Please contact us if you have questions about the application process. Please refer to the standard application parameters below.

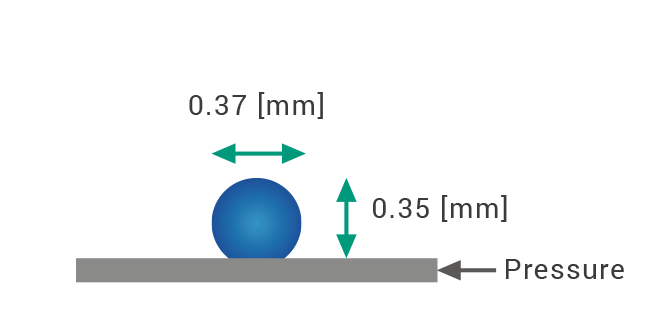

※Application speed: 15 mm/s.

*Please swipe left or right to view table below.

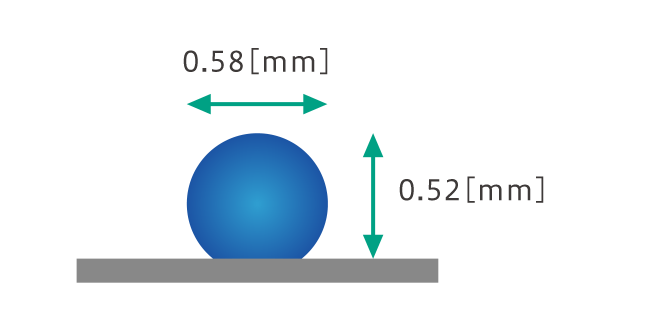

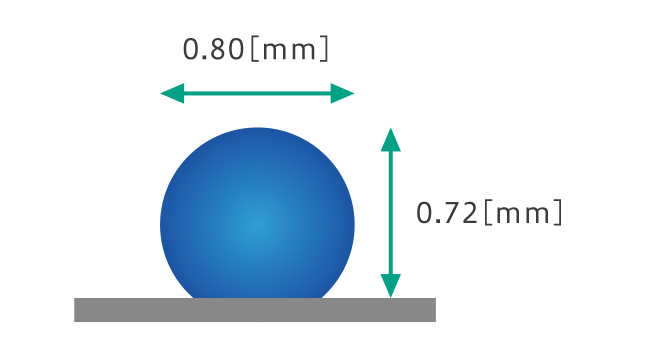

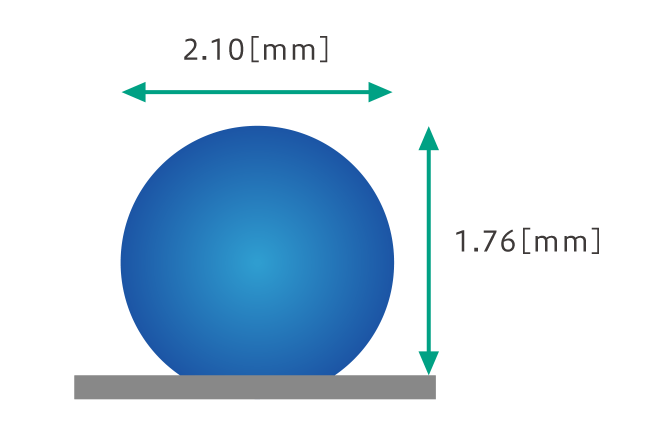

| Needle parameters | Gasket cross-section | Pressure[MPa] |

|---|---|---|

| 21G(IDφ0.51[mm]) Pressure→Needle penetration:0.51[mm] |

|

0.40 |

| 20G(IDφ0.58[mm]) Pressure→Needle penetration:0.79[mm] |

|

0.45 |

| 17G(IDφ1.12[mm]) Pressure→Needle penetration:1.0[mm] |

|

0.15 |

| 13G(IDφ1.99 [mm]) Pressure→Needle penetration:1.94[mm] |

|

0.15 |

- Customization

- We also develop custom products to meet our customers’ individual needs. Contact us today!