- TOP

- αGEL Products

- Heat Dissipation/Non-Silicone-Type

αGEL Products

Non-Silicone-Type

These non-silicone type heat dissipation materials do not contain low molecular weight siloxane. We have a rich product lineup such as sheets, liquids (grease, putty), double-sided tapes, etc. Since low molecular weight siloxane gas is not generated, problems such as contact failure do not occur.

- 特長

- ●Does not contain low molecular weight siloxane.

- ●No low molecular weight siloxane gas is generated, making it usable near contacts or switches preventing problems such as contact failure etc.

- ●Despite being a non-silicone material, it achieves high thermal conductivity and a wide temperature range (-60℃ to 150℃).

- ●We offer various product types such as liquids (grease, putty), double-sided tapes and sheets.

- Application Example

(Sheet-Type)

- Soft thermal conductive GEL effectively transfers heat generated from an IC-Chip to the heatsink, preventing PC malfunction and device damage. Soft thermal conductive GEL paste/grease is ideal for areas where sheet material is not applicable.

- Application Example

(Liquid-Type)

- Fill gaps around the heat source for improved heat dissipation.Eliminate running and vaporization problems. Easily spreads over heat generating devices.

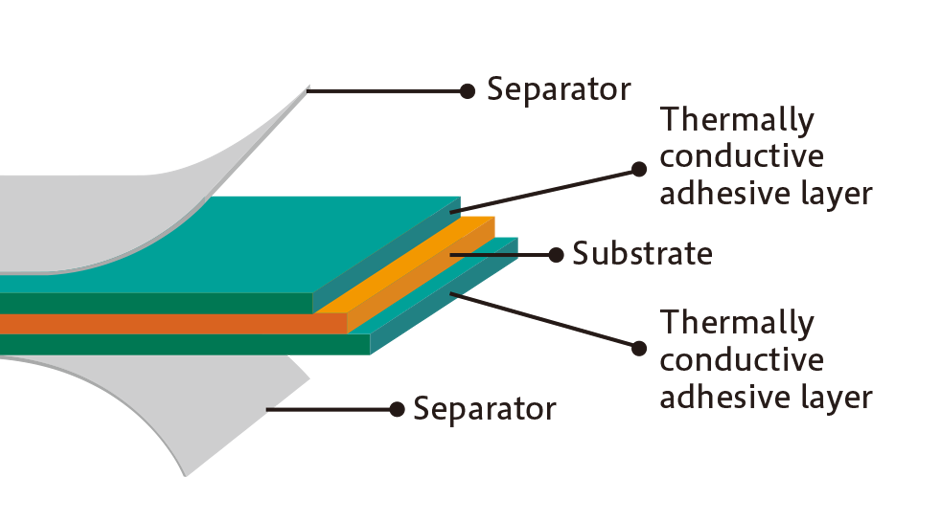

- Layer Structure

(Double-Sided Tapes)

- The structure is sandwiched between separators on both sides. It can be delivered in sheet or roll form.

Table of thermal conductivity (By product)

Product lineup(By product / By hardness)(Non-Silicone-Type)

Product Details

*Please swipe left or right to view table below.

【Sheet-Type Products Physical Characteristics】

| Property | Unit | Product | Remarks | ||||

|---|---|---|---|---|---|---|---|

| COH-N01560 | COH-N03060 | COH-N05055 | COH-N09050 | COH-N13050 | |||

| Thermal conductivity |

W/mK | 1.5 | 3 | 5 | 9 | 13 | ASTM D5470 |

| Hardness | ShoreOO | 60 | 60 | 55 | 50 | 50 | ASTM D2240 |

| Thickness | mm | 0.5~5.0 | 0.5~5.0 | 0.5~5.0 | 0.5~5.0 | 0.5~5.0 | - |

| Temperature range |

℃ | -60~125 | -60~125 | -60~125 | -60~125 | -60~125 | - |

| Color | - | Gray | Red | Gray | Pink | Gray | - |

| Material | - | Non-Silicone | Non-Silicone | Non-Silicone | Non-Silicone | Non-Silicone | - |

| Reinforced layer | - | - | - | - | - | - | - |

| Density | - | 2.2 | 2.6 | 3.2 | 3.4 | 3.3 | ASTM D792 |

| Flame retardance | - | V-0 Equivalent | V-0 Equivalent | - | - | - | UL94 |

| Dielectric breakdown strength | kV/mm | 10 | 10 | 8 | 8 | 8 | ASTM D149 |

| Volume resistivity | Ω-m | >1010 | >1010 | >1010 | >1010 | >1010 | ASTM D257 |

| Surface resistivity | Ω | >1011 | >1011 | >1011 | >1011 | >1011 | ASTM D257 |

▼Show all items

| Property | Unit |

|---|---|

| Thermal conductivity |

W/mK |

| Hardness | ShoreOO |

| Thickness | mm |

| Temperature range |

℃ |

| Color | - |

| Material | - |

| Reinforced layer |

- |

| Density | - |

| Flame retardance |

- |

| Dielectric breakdown strength |

kV/mm |

| Volume resistivity |

Ω-m |

| Surface resistivity |

Ω |

| Product | Remarks | ||||

|---|---|---|---|---|---|

| COH-N01560 | COH-N03060 | COH-N05055 | COH-N09050 | COH-N13050 | |

| 1.5 | 3 | 5 | 9 | 13 | ASTM D5470 |

| 60 | 60 | 55 | 50 | 50 | ASTM D2240 |

| 0.5~5.0 | 0.5~5.0 | 0.5~5.0 | 0.5~5.0 | 0.5~5.0 | - |

| -60~125 | -60~125 | -60~125 | -60~125 | -60~125 | - |

| Gray | Red | Gray | Pink | Gray | - |

| Non-Silicone | Non-Silicone | Non-Silicone | Non-Silicone | Non-Silicone | - |

| - | - | - | - | - | - |

| 2.2 | 2.6 | 3.2 | 3.4 | 3.3 | ASTM D792 |

| V-0 Equivalent | V-0 Equivalent | - | - | - | UL94 |

| 10 | 10 | 8 | 8 | 8 | UL94 |

| >1010 | >1010 | >1010 | >1010 | >1010 | ASTM D257 |

| >1011 | >1011 | >1011 | >1011 | >1011 | ASTM D257 |

※Above data are measured data, not guaranteed specifications.

*Please swipe left or right to view table below.

【Liquid-Type Products Physical Characteristics】

| Property | Unit | Product | Remarks | |||

|---|---|---|---|---|---|---|

| DP- N01396-GR |

DP- N03243-GR |

DP- N04593-GR |

DP- N03515-PA |

|||

| Thermal conductivity |

W/mK | 1.3 | 3.2 | 4.5 | 3.5 | ASTM D5470 |

| Viscosity | PaS | 96 | 43 | 93 | - | ISO 3219 |

| - | - | - | 15,000 | DIN 53018 | ||

| Temperature range |

℃ | -60~150 | -60~150 | -60~150 | -60~150 | - |

| Color | - | White | Gray | Gray | Gray | - |

| Material | - | Non-Silicone | Non-Silicone | Non-Silicone | Non-Silicone | - |

| Density | - | 2.2 | 1.9 | 2.1 | 3.0 | ASTM D792 |

| Dielectric breakdown strength | V/mil | 350 | - | - | 300 | ASTM D149 |

| Volume resistivity |

Ω-m | >1011 | - | - | >1013 | ASTM D257 |

▼Show all items

| Property | Unit |

|---|---|

| Thermal conductivity |

W/mK |

| Viscosity | PaS |

| Temperature range |

℃ |

| Color | - |

| Material | - |

| Density | - |

| Dielectric breakdown strength |

kV/mm |

| Volume resistivity |

Ω-m |

| Product | Remarks | |||

|---|---|---|---|---|

| DP-N01396-GR | DP-N03243-GR | DP-N04593-GR | DP-N03515-PA | |

| 1.3 | 3.2 | 4.5 | 3.5 | ASTM D5470 |

| 96 | 43 | 93 | - | ISO 3219 |

| - | - | - | 15,000 | DIN 53018 |

| -60~150 | -60~150 | -60~150 | -60~150 | - |

| White | Gray | Gray | Gray | - |

| Non-Silicone | Non-Silicone | Non-Silicone | Non-Silicone | - |

| 2.2 | 1.9 | 2.1 | 3.0 | ASTM D792 |

| 350 | - | - | 300 | ASTM D149 |

| >1011 | - | - | >1013 | ASTM D257 |

※Above data are measured data, not guaranteed specifications.

*Please swipe left or right to view table below.

【Double Sided Tape Products Physical Characteristics】

| Property | Unit | Conditions | Product | Remarks | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| TP-N009-GF | TP-N010-GF | TP-N012-GF | TP-N012-PI | TP-N020 | |||||||||

| Thermal conductivity |

W/mK | - | 0.9 | 1.0 | 1.2 | 1.2 | 2.0 | ASTM D5470 |

|||||

| Thickness | mm | - | 0.15 | 0.25 | 0.15 | 0.25 | 0.15 | 0.25 | 0.1 | 0.14 | 0.25 | 0.38 | - |

| Temperature range |

℃ | - | -60~120 | -60~120 | -60~120 | -60~120 | -60~120 | - | |||||

| Color | - | - | White | White | White | Brown | White | - | |||||

| Material | - | - | acrylic | acrylic | acrylic | acrylic | acrylic | - | |||||

| Reinforced layer |

- | - | Glass Fiber | Glass Fiber | Glass Fiber | Polyimide | - | - | |||||

| Density | - | - | 1.6 | 1.8 | 1.7 | 1.6 | 1.8 | ASTM D792 |

|||||

| Flame retardance |

- | - | - | V-0 Equivalent | - | - | - | UL94 | |||||

| Dielectric strength |

kV | DCV | 3 | 4 | 3 | 4 | 4 | 5 | 5 | 6 | 5 | 7 | ASTM D149 |

| ACV | 2 | 3 | 2 | 3 | 3 | 4 | 4 | 5 | 4 | 6 | |||

| Volume resistivity |

Ω-m | - | >1010 | >1011 | >1011 | >1012 | >109 | ASTM D257 |

|||||

| Surface resistivity |

Ω | - | >1010 | >1011 | >1011 | >1012 | >1010 | ASTM D257 |

|||||

| Initial tack | cm | - | 10 | 8 | 11 | 8 | 14 | 12 | 13 | 13 | 10 | 8 | PSTC-6 |

| Lap shear strength |

N/㎠ | - | 60 | 60 | 50 | 50 | 55 | 60 | 60 | 60 | 45 | 60 | ASTM D1002 |

| 90° Peeling strength |

N/inch | 25℃ 72h | >10 | >12 | >5 | >6 | >6 | >8 | >10 | >10 | >9 | >11 | ASTM D3330 |

| 80℃ 1000h |

>14 | >20 | >14 | >20 | >10 | >15 | >14 | >15 | >16 | >20 | |||

| 85℃/ 85%RH 1000h |

>20 | >25 | >20 | >24 | >18 | >22 | >16 | >18 | >22 | >25 | |||

| -40℃⇔ 120℃ 500 cycle |

>15 | >20 | >27 | >28 | >13 | >19 | >14 | >14 | >14 | >17 | |||

| Die shear strength |

N/㎠ | 25℃ | 107 | 94 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | - |

| 80℃ | 70 | 70 | 70 | 70 | 65 | 65 | 50 | 50 | 50 | 70 | |||

| Holding Power |

Min | 1kg 25℃ | >10000 | >10000 | >10000 | >10000 | >10000 | PSTC-7 | |||||

| 1kg 80℃ | >10000 | >10000 | >10000 | >10000 | >10000 | ||||||||

▼Show all items

| Property | Unit |

|---|---|

| Thermal conductivity |

W/mK |

| Thickness | mm |

| Temperature range |

℃ |

| Color | - |

| Material | - |

| Reinforced layer |

- |

| Density | - |

| Flame retardance |

- |

| Dielectric strength |

kV |

| Volume resistivity |

Ω-m |

| Surface resistivity |

Ω |

| Initial tack |

cm |

| Lap shear strength |

N/㎠ |

| 90° Peeling strength |

N/inch |

| Die shear strength |

N/㎠ |

| Holding Power |

Min |

| 条件 | Product | Remarks | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| TP-N009-GF | TP-N010-GF | TP-N012-GF | TP-N012-PI | TP-N020 | |||||||

| - | 0.9 | 1.0 | 1.2 | 1.2 | 2.0 | ASTM D5470 | |||||

| - | 0.15 | 0.25 | 0.15 | 0.25 | 0.15 | 0.25 | 0.1 | 0.14 | 0.25 | 0.38 | - |

| - | -60~120 | -60~120 | -60~120 | -60~120 | -60~120 | - | |||||

| - | White | White | White | Brown | White | - | |||||

| - | acrylic | acrylic | acrylic | acrylic | acrylic | - | |||||

| - | Glass Fiber | Glass Fiber | Glass Fiber | Polyimide | - | - | |||||

| - | 1.6 | 1.8 | 1.7 | 1.6 | 1.8 | ASTM D792 | |||||

| - | - | V-0 Equivalent | - | - | - | UL94 | |||||

| DCV | 3 | 4 | 3 | 4 | 4 | 5 | 5 | 6 | 5 | 7 | ASTM D149 |

| ACV | 2 | 3 | 2 | 3 | 3 | 4 | 4 | 5 | 4 | 6 | |

| - | >1010 | >1011 | >1011 | >1012 | >109 | ASTM D257 | |||||

| - | >1010 | >1011 | >1011 | >1012 | >1010 | ASTM D257 | |||||

| - | 10 | 8 | 11 | 8 | 14 | 12 | 13 | 13 | 10 | 8 | PSTC-6 |

| - | 60 | 60 | 50 | 50 | 55 | 60 | 60 | 60 | 45 | 60 | ASTM D1002 |

| 25℃ 72h | >10 | >12 | >5 | >6 | >6 | >8 | >10 | >10 | >9 | >11 | ASTM D3330 |

| 80℃ 1000h |

>14 | >20 | >14 | >20 | >10 | >15 | >14 | >15 | >16 | >20 | |

| 85℃/ 85%RH 1000h |

>20 | >25 | >20 | >24 | >18 | >22 | >16 | >18 | >22 | >25 | |

| -40℃⇔ 120℃ 500 cycle |

>15 | >20 | >27 | >28 | >13 | >19 | >14 | >14 | >14 | >17 | |

| 25℃ | 107 | 94 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | - |

| 80℃ | 70 | 70 | 70 | 70 | 65 | 65 | 50 | 50 | 50 | 70 | |

| 1kg 25℃ | >10000 | >10000 | >10000 | >10000 | >10000 | PSTC-7 | |||||

| 1kg 80℃ | >10000 | >10000 | >10000 | >10000 | >10000 | ||||||

※Above data are measured data, not guaranteed specifications.

Product Locator

*Please swipe left or right to view table below.

-

Product

CategoryProduct

LineProduct Type

(Characteristic)Abbreviation Thermal

conductivity(W/mK)

(MIN〜MAX)Hardness/Viscosity

(Soft~Hard)Thickness(mm)

(MIN〜MAX)Characteristics Delivery as Sheet-Type COH Highly conductive

productsVS

(Very Soft)8.0〜20 ShoreOOO65〜

ShoreOO 350.5〜5.0 Extremely high thermal conductivity

+High softnessStandard Sheet

Custom cut partSheet-Type COH Standard

productsG(Gel)

LB(Low oil Bleed)

S(Standard)1.2〜12 ShoreOO10〜

ShoreA 400.1〜15.0 High Softness

Little oil bleeding

Added stiffeners"Standard Sheet

Custom cut part"Sheet-Type COH High electronic

insulation

productsHI

(High electronic Insulation)1.5〜3.0 ShoreA 80 0.15〜0.35 High electric insulation Standard Sheet

Custom cut partSheet-Type COH Non-silicone

productsN

(Non-Silicone)1.5〜13 ShoreOO50〜

ShoreOO 600.5〜5.0 Free of low molecular

weight siloxaneStandard Sheet

Custom cut partLiquid-Type DP Grease

productsGR

(Grease)1.1〜6.0 16.5(PaS)〜3,090(PaS) - Low viscosity Bottle Liquid-Type DP Putty

productsPT

(Putty)3.5〜8.0 3,500(PaS)〜20,000(PaS) - High viscosity Syringe

CartridgeLiquid-Type DP 2 Component

productsTC

(Two-Component curing)0.55〜5.0 ShoreOO50〜

ShoreA 55- Room temp.

Heat curingSyringe

CartridgeLiquid-Type DP Non-silicone

productsN

(Non-Silicone)1.3〜4.5 43(PaS)〜15,000(PaS) - Free of low molecular

weight siloxaneSyringe

Cartridge

BottleEMI

Shielding

TypeRE Electromagnetic

wave absorption

productsEA

(Electromagnetic Absorption)0.7〜4.0 ShoreOO 39〜

ShoreOO 550.5〜5.0 EMI Shielding

+Heat Dissipation

Electromagnetic wave absorptionStandard Sheet

Custom cut partEMI

Shielding

TypeRE Electromagnetic

wave shielding

productsES

(Electromagnetic Shield)3.0〜5.0 ShoreOO50〜

ShoreOO 550.5〜5.0 EMI Shielding

+Heat Dissipation

Electromagnetic wave shieldingStandard Sheet

Custom cut partDouble-Sided Tapes TP Silicone

productsSi

(Silicone)1.2〜1.8 - 0.15〜0.25 High Adhesion

+Heat DissipationSheet

RollDouble-Sided Tapes TP Non-silicone

productsN

(Non-Silicone)0.9〜2.0 - 0.1〜0.38 High Adhesion

+Heat Dissipation

Free of low molecular weight siloxaneSheet

RollProduct

CategorySheet-Type Sheet-Type Sheet-Type Sheet-Type Liquid-Type Liquid-Type Liquid-Type Liquid-Type EMI Shielding

TypeEMI Shielding

TypeDouble-Sided

TapesDouble-Sided

TapesProduct

LineProduct Type

(Characteristic)Abbreviation Thermal conductivity

(W/mK)

(MIN〜MAX)Hardness/Viscosity

(Soft~Hard)Thickness(mm)

(MIN〜MAX)Characteristics Delivery as COH Highly conductive

productsVS

(Very Soft)8.0〜20 ShoreOOO65〜

ShoreOO 350.5〜5.0 Extremely high thermal conductivity

+High softnessStandard Sheet

Custom cut partCOH Standard products G(Gel)

LB(Low oil Bleed)

S(Standard)1.2〜12 ShoreOO10〜

ShoreA 400.1〜15.0 High Softness

Little oil bleeding

Added stiffenersStandard Sheet

Custom cut partCOH High electronic

insulation productsHI

(High electronic Insulation)1.5〜3.0 ShoreA 80 0.15〜0.35 High electric insulation Standard Sheet

Custom cut partCOH Non-silicone products N

(Non-Silicone)1.5〜13 ShoreOO50〜

ShoreOO 600.5〜5.0 Free of low molecular

weight siloxaneStandard Sheet

Custom cut partDP Grease products GR

(Grease)1.1〜6.0 16.5(PaS)〜3,090(PaS) - Low viscosity Bottle DP Putty products PT

(Putty)3.5〜8.0 3,500(PaS)〜20,000(PaS) - High viscosity Syringe

CartridgeDP 2 Component products TC

(Two-Component curing)0.55〜5.0 ShoreOO50〜

ShoreA 55- Room temp./

Heat curingSyringe

CartridgeDP Non-silicone products N

(Non-Silicone))1.3〜4.5 43(PaS)〜15,000(PaS) - Free of low molecular

weight siloxaneSyringe

Cartridge

BottleRE Electromagnetic wave absorption products EA

(Electromagnetic Absorption)0.7〜4.0 ShoreOO 39〜

ShoreOO 550.5〜5.0 EMI Shielding

+Heat Dissipation

Electromagnetic

wave absorptionStandard Sheet

Custom cut partRE Electromagnetic wave shielding products ES

(Electromagnetic Shield)3.0〜5.0 ShoreOO50〜

ShoreOO 550.5〜5.0 EMI Shielding

+Heat Dissipation

Electromagnetic

wave shieldingStandard Sheet

Custom cut partTP Silicone products Si

(Silicone)1.2〜1.8 - 0.15〜0.25 High Adhesion

+Heat DissipationSheet

RollTP Non-silicone products N

(Non-Silicone)0.9〜2.0 - 0.1〜0.38 High Adhesion

+Heat Dissipation

Free of low molecular

weight siloxanSheet

Roll

- Customization

- We also develop custom products to meet our customers’ individual needs. Contact us today!