- TOP

- αGEL Products

- Heat Dissipation/Liquid-Type(DP Line)

αGEL Products

Liquid-Type(DP Line)

The DP liquid type (grease, putty, two-component curing) heat dissipation materials can be filled and applied to heat sources to fill small gaps to the cooling parts such as heat sinks. The molecular structure was manipulated, such that they don't drip or vaporize to provide stable heat dissipation over the long term.

- Characteristics

- ●Extremely low thermal resistance and exhibits excellent heat dissipation performance.

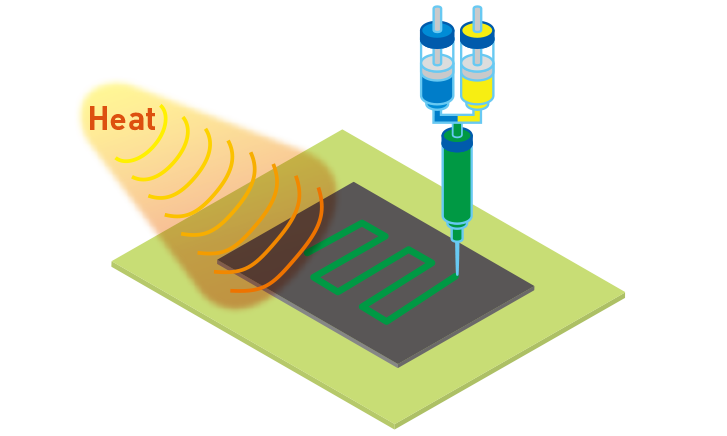

- ●By using filling equipment, it is possible to automate the dispensing process making it easy to handle.

- ●The two-component material cures after mixing for high reliability and great dispensing flow. It retains its flexibility even after curing, reducing the load.

- ●Cross-linked particles of Alpha GEL DP Line eliminate running and vaporization problems seen with traditional grease and phase change materials.

- ●Good electrical insulation.

- ●Even the smallest cracks and crevices can be filled with Alpha GEL DP Line, eliminating air gaps and ensuring the most efficient heat transfer possible.

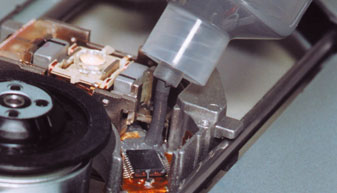

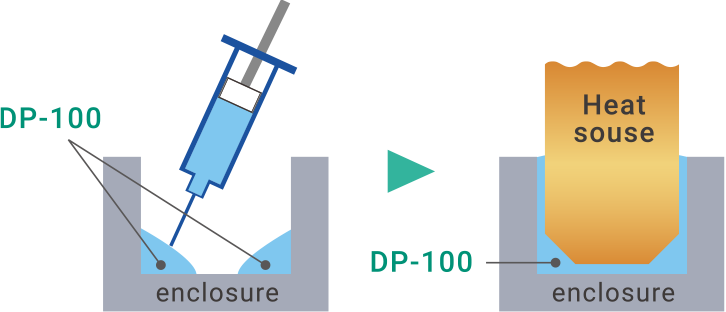

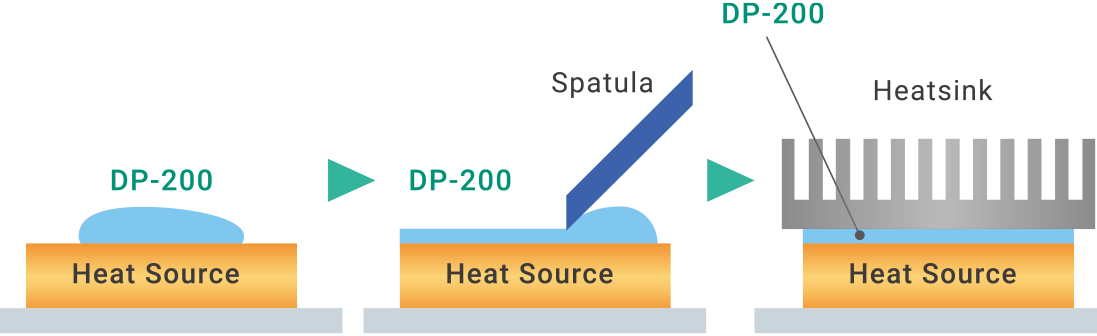

- Application Example

- Fill gaps around the heat source for improved heat dissipation.Eliminate running and vaporization problems. Easily spreads over heat generating devices.

- Technical Information

-

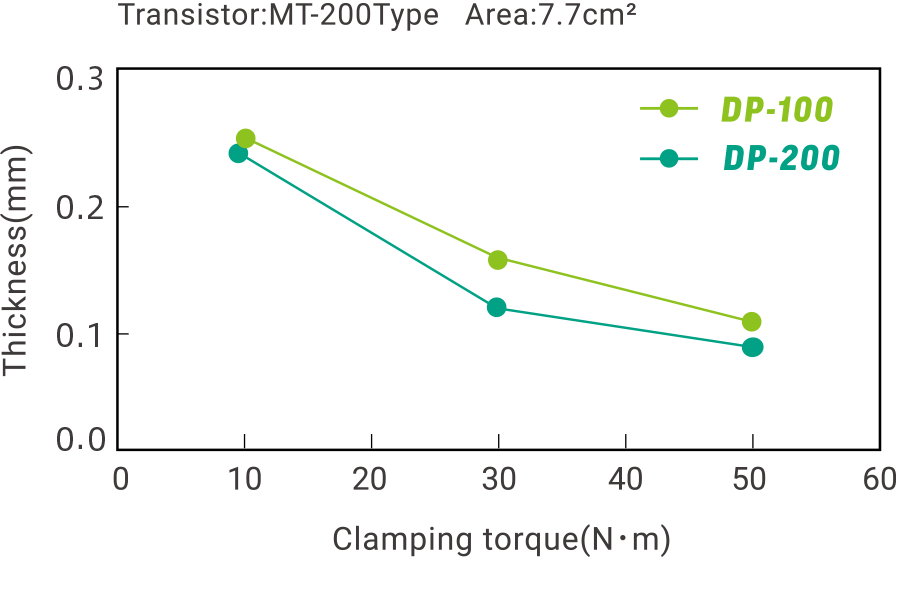

[Clamping Torque Dependency]

[Thermal Resistance]

Transistor:MT-200Type Heat input:20V

Thickness(㎜) 0.10 0.15 0.20 0.30 DP-100 - 0.13 0.15 0.18 DP-200 0.13 - 0.17 0.22 (℃/W)

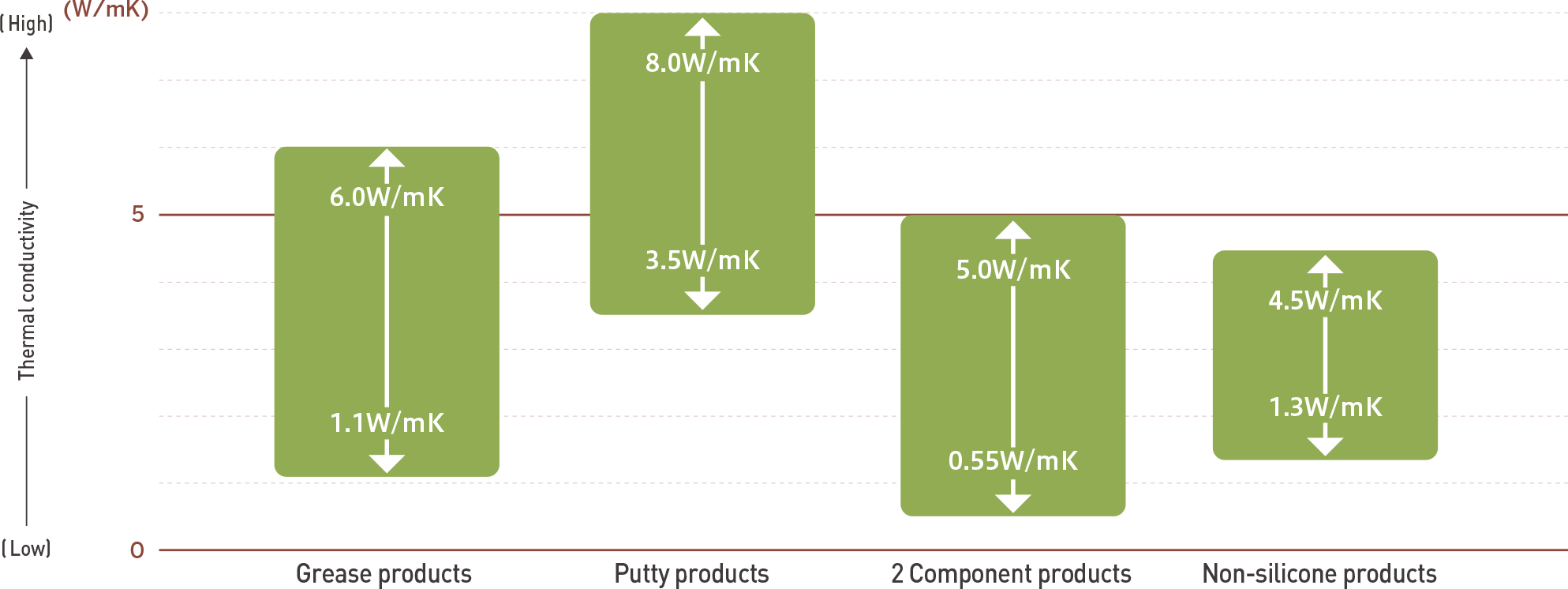

Table of thermal conductivity (By product)

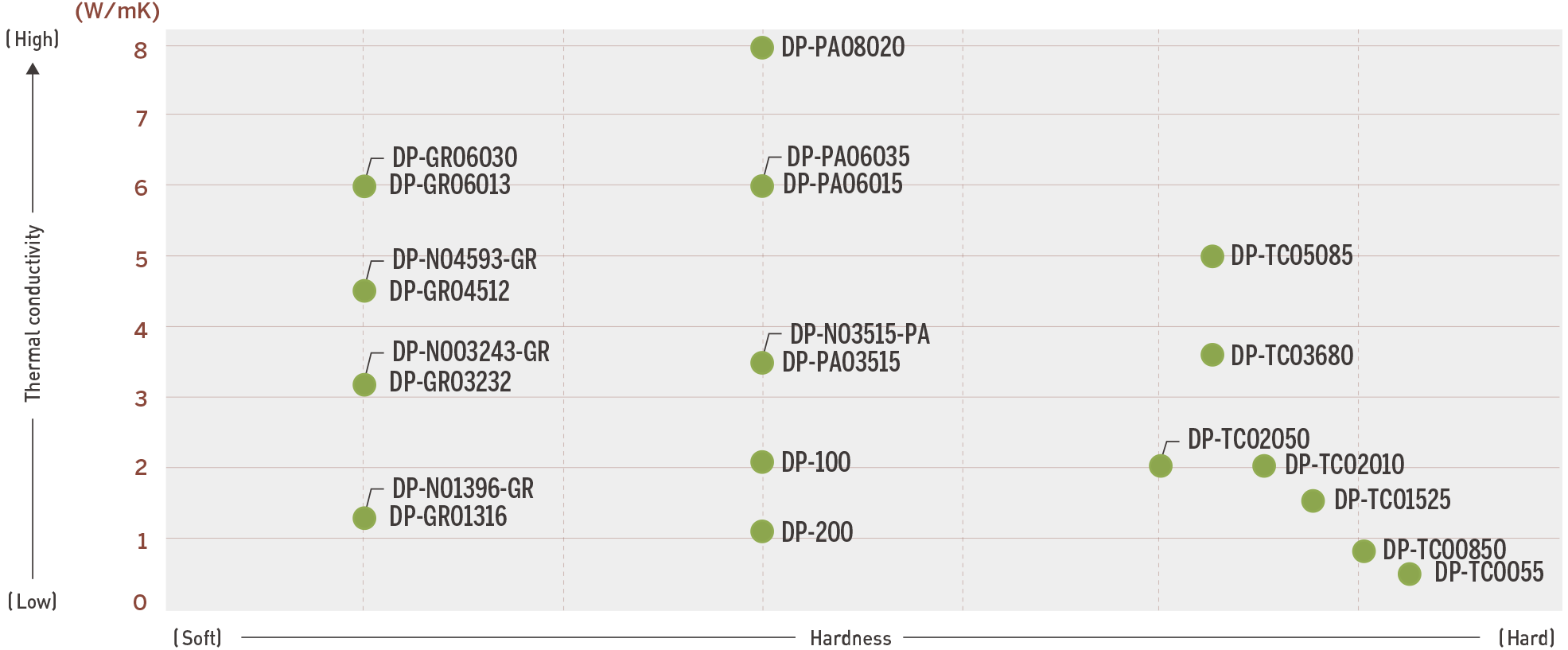

Product lineup(By product / By hardness)(Liquid-Type)

Product Details

*Please swipe left or right to view table below.

【DP Line / Grease Products Physical Characteristics】

| Property | Unit | Product | Remarks | ||||||

|---|---|---|---|---|---|---|---|---|---|

| DP-100 | DP-200 | DP-GR01316 | DP-GR03232 | DP-GR04512 | DP-GR06013 | DP-GR06030 | |||

| Thermal conductivity |

W/mK | 2.1 | 1.1 | 1.3 | 3.2 | 4.5 | 6.0 | 6.0 | ASTM D5470 |

| Viscosity | PaS | 3,090 | 2,214 | - | - | - | - | 300 | ISO 3219 |

| - | - | 16.5 | 322 | 126 | 136 | - | ASTM D2196 | ||

| Temperature range |

℃ | -40~200 | -40~150 | -60~180 | -60~180 | -60~180 | -60~180 | -60~160 | - |

| Color | - | Gray | Gray | White | Gray | Gray | Gray | White | - |

| Material | - | Silicone | Silicone | Silicone | Silicone | Silicone | Silicone | Silicone | - |

| Density | - | 2.8 | 2.6 | 2.2 | 2.7 | 2.0 | 2.0 | 3.3 | ASTM D792 |

| Dielectric breakdown strength |

V/mil | 130 | 130 | 350 | 280 | - | - | 200 | ASTM D149 |

| Volume resistivity |

Ω-m | 4.2*1010 | 4.5*1012 | >1011 | >1011 | - | - | >1012 | ASTM D257 |

▼Show all items

| Property | Unit |

|---|---|

| Thermal conductivity |

W/mK |

| Viscosity | PaS |

| Temperature range |

℃ |

| Color | - |

| Material | - |

| Density | - |

| Dielectric breakdown strength |

V/mil |

| Volume resistivity |

Ω-m |

| Product | Remarks | ||||||

|---|---|---|---|---|---|---|---|

| DP-100 | DP-200 | DP-GR01316 | DP-GR03232 | DP-GR04512 | DP-GR06013 | DP-GR06030 | |

| 2.1 | 1.1 | 1.3 | 3.2 | 4.5 | 6.0 | 6.0 | ASTM D5470 |

| 3,090 | 2,214 | - | - | - | - | 300 | ISO 3219 |

| - | - | 16.5 | 322 | 126 | 136 | - | ASTM D2196 |

| -40~200 | -40~150 | -60~180 | -60~180 | -60~180 | -60~180 | -60~160 | - |

| Gray | Gray | White | Gray | Gray | Gray | White | - |

| Silicone | Silicone | Silicone | Silicone | Silicone | Silicone | Silicone | - |

| 2.8 | 2.6 | 2.2 | 2.7 | 2.0 | 2.0 | 3.3 | ASTM D792 |

| 130 | 130 | 350 | 280 | - | - | 200 | ASTM D149 |

| 4.2*1010 | 4.5*1012 | >1011 | >1011 | - | - | >1012 | ASTM D257 |

※Silicone oil may bleed depending upon conditions.

※Low molecular siloxane is included in this product which basically composed of silicone.

※Above data are measured data, not guaranteed specifications.

*Please swipe left or right to view table below.

【DP Line / Putty Products Physical Characteristics】

| Property | Unit | Product | Remarks | |||

|---|---|---|---|---|---|---|

| DP- PA03515 |

DP- PA06015 |

DP- PA06035 |

DP- PA08020 |

|||

| Thermal conductivity |

W/mK | 3.5 | 6.0 | 6.0 | 8.0 | ASTM D5470 |

| Viscosity | PaS | - | - | 3,500 | - | ISO 3219 |

| 15,000 | 15,000 | - | 20,000 | DIN 53018 | ||

| Temperature range |

℃ | -60~180 | -60~180 | -60~180 | -60~180 | - |

| Color | - | Blue | Blue | Blue | Gray | - |

| Material | - | Silicone | Silicone | Silicone | Silicone | - |

| Density | - | 3.0 | 3.3 | 3.3 | 3.4 | ASTM D792 |

| Flame retardance |

- | V-0 Equivalent | V-0 Equivalent | V-0 Equivalent | V-0 Equivalent | UL94 |

| Dielectric breakdown strength |

V/mil | 300 | 300 | 300 | 300 | ASTM D149 |

| Volume resistivity |

Ω-m | >1013 | >1013 | >1013 | >1013 | ASTM D257 |

▼Show all items

| Property | Unit |

|---|---|

| Thermal conductivity |

W/mK |

| Viscosity | PaS |

| Temperature range |

℃ |

| Color | - |

| Material | - |

| Density | - |

| Flame retardance |

- |

| Dielectric breakdown strength |

V/mil |

| Volume resistivity |

Ω-m |

| Product | Remarks | |||

|---|---|---|---|---|

| DP- PA03515 |

DP- PA06015 |

DP- PA06035 |

DP- PA08020 |

|

| 3.5 | 6.0 | 6.0 | 8.0 | ASTM D5470 |

| - | - | 3,500 | - | ISO 3219 |

| 15,000 | 15,000 | - | 20,000 | DIN 53018 |

| -60~180 | -60~180 | -60~180 | -60~180 | - |

| Blue | Blue | Blue | Gray | - |

| Silicone | Silicone | Silicone | Silicone | - |

| 3.0 | 3.3 | 3.3 | 3.4 | ASTM D792 |

| V-0 Equivalent | V-0 Equivalent | V-0 Equivalent | V-0 Equivalent | UL94 |

| 300 | 300 | 300 | 300 | ASTM D149 |

| >1013 | >1013 | >1013 | >1013 | ASTM D257 |

※Silicone oil may bleed depending upon conditions.

※Low molecular siloxane is included in this product which basically composed of silicone.

※Above data are measured data, not guaranteed specifications.

*Please swipe left or right to view table below.

【DP Line / 2 Components Products Physical Characteristics】

| Property | Unit | Product | Remarks | ||||||

|---|---|---|---|---|---|---|---|---|---|

| DP- TC00555 |

DP- TC00850 |

DP- TC01525 |

DP- TC02010 |

DP- TC02050 |

DP- TC03680 |

DP- TC05085 |

|||

| Thermal conductivity |

W/mK | 0.55 | 0.8 | 1.5 | 2.0 | 2.0 | 3.6 | 5.0 | ASTM D5470 |

| Viscosity (Initial) |

PaS | A/B=5000/ 10(cP) |

A+B=5 | A+B=20 | A+B=15 | A/B=120/110 | A/B=47/48 | A/B=110/80 | ISO 3219 |

| Hardness (After curing) |

ShoreA | 55 | 50 | 25 | 10 | - | - | - | ASTMD2240 |

| ShoreOO | - | - | - | - | 50 | 80 | 85 | ||

| Temperature range |

℃ | -60~160 | -60~180 | -60~180 | -60~180 | -60~200 | -55~205 | -55~200 | - |

| Color | A/B | White/ Translucent |

White/White | White/Pink | White/Gray | White/Gray | Blue/White | Red/White | - |

| Material | - | Silicone | Silicone | Silicone | Silicone | Silicone | Silicone | Silicone | - |

| Density | - | 1.35 | 1.8 | 2.0 | 2.1 | 2.2 | 3.0 | 3.3 | ASTM D792 |

| Flame retardance |

- | - | - | - | - | - | V-0 Equivalent | V-0 Equivalent | UL94 |

| Dielectric breakdown strength |

V/mil | 25 | 350 | 350 | 350 | - | - | - | ASTM D149 |

| Volume resistivity |

Ω-m | >1013 | >1011 | >1012 | >1013 | >1010 | >1012 | >1012 | ASTM D257 |

| Mixing ratio | A/B | 100/10 | 100/3 | 1/1 | 1/1 | 1/1 | 1/1 | 1/1 | - |

| Curing Conditions |

Min | 25℃:48 | 25℃:7(days) | 25℃:300 60℃:30 100℃:5 (By Taica) |

25℃:300 60℃:30 100℃:5 (By Taica) |

25℃:30~35 100℃:1.2 120℃:0.3 (By Taica) |

25℃:169 30℃:140 40℃:105 50℃:69 60℃:40 70℃:31 80℃:17 90℃:7 100℃:3 120℃:1 |

25℃:108 30℃:86 40℃:50 50℃:35 60℃:26 70℃:20 80℃:9 90℃:4 100℃:2 120℃:0.5 |

ASTM D1646 |

▼Show all items

| Property | Unit |

|---|---|

| Thermal conductivity |

W/mK |

| Viscosity (Initial) |

PaS |

| Hardness (After curing) |

ShoreA |

| ShoreOO | |

| Temperature range |

℃ |

| Color | A/B |

| Material | - |

| Density | - |

| Flame retardance | - |

| Dielectric breakdown strength |

V/mil |

| Volume resistivity |

Ω-m |

| Mixing ratio | A/B |

| Curing Conditions |

Min |

| Product | Remarks | ||||||

|---|---|---|---|---|---|---|---|

| DP- TC00555 |

DP- TC00850 |

DP- TC01525 |

DP- TC02010 |

DP- TC02050 |

DP- TC03680 |

DP- TC05085 |

|

| 0.55 | 0.8 | 1.5 | 2.0 | 2.0 | 3.6 | 5.0 | ASTM D5470 |

| A/B=5000/10(cP) | A+B=5 | A+B=20 | A+B=15 | A/B=120/110 | A/B=47/48 | A/B=110/80 | ISO 3219 |

| 55 | 50 | 25 | 10 | - | - | - | ASTMD2240 |

| - | - | - | - | 50 | 80 | 85 | |

| -60~160 | -60~180 | -60~180 | -60~180 | -60~200 | -55~205 | -55〜200 | - |

| White/ Translucent |

White/ White |

White/ Pink |

White/ Gray |

White/ Gray |

Blue/ White |

Red/White | - |

| Silicone | Silicone | Silicone | Silicone | Silicone | Silicone | Silicone | - |

| 1.35 | 1.8 | 2.0 | 2.1 | 2.2 | 3.0 | 3.3 | ASTM D792 |

| - | - | - | - | - | V-0 Equivalent | V-0 Equivalent | UL94 |

| 25 | 350 | 350 | 350 | - | - | - | ASTM D149 |

| >1013 | >1011 | >1012 | >1013 | >1010 | >1012 | >1012 | ASTM D257 |

| 100/10 | 100/3 | 1/1 | 1/1 | 1/1 | 1/1 | 1/1 | - |

| 25℃:48 | 25℃:7(days) | 25℃:300 60℃:30 100℃:5 (By Taica) |

25℃:300 60℃:30 100℃:5 (By Taica) |

25℃:30~35 100℃:1.2 120℃:0.3 (By Taica) |

25℃:169 30℃:140 40℃:105 50℃:69 60℃:40 70℃:31 80℃:17 90℃:7 100℃:3 120℃:1 |

25℃:108 30℃:86 40℃:50 50℃:35 60℃:26 70℃:20 80℃:9 90℃:4 100℃:2 120℃:0.5 |

ASTM D1646 |

※Silicone oil may bleed depending upon conditions.

※Low molecular siloxane is included in this product which basically composed of silicone.

※Above data are measured data, not guaranteed specifications.

*Please swipe left or right to view table below.

【DP Line / Non-Silicone Type Products Physical Characteristics】

| Property | Unit | Product | Remarks | |||

|---|---|---|---|---|---|---|

| DP- N01396-GR |

DP- N03243-GR |

DP- N04593-GR |

DP- N03515-PA |

|||

| Thermal conductivity |

W/mK | 1.3 | 3.2 | 4.5 | 3.5 | ASTM D5470 |

| Viscosity | PaS | 96 | 43 | 93 | - | ISO 3219 |

| - | - | - | 15,000 | DIN 53018 | ||

| Temperature range |

℃ | -60~150 | -60~150 | -60~150 | -60~150 | - |

| Color | - | White | Gray | Gray | Gray | - |

| Material | - | Non-Silicone | Non-Silicone | Non-Silicone | Non-Silicone | - |

| Density | - | 2.2 | 1.9 | 2.1 | 3.0 | ASTM D792 |

| Dielectric breakdown strength |

V/mil | 350 | - | - | 300 | ASTM D149 |

| Volume resistivity |

Ω-m | >1011 | - | - | >1013 | ASTM D257 |

▼Show all items

| Property | Unit |

|---|---|

| Thermal conductivity |

W/mK |

| Viscosity | PaS |

| Temperature range |

℃ |

| Color | - |

| Material | - |

| Density | - |

| Dielectric breakdown strength |

V/mil |

| Volume resistivity |

Ω-m |

| Product | Remarks | |||

|---|---|---|---|---|

| DP- N01396-GR |

DP- N03243-GR |

DP- N04593-GR |

DP- N03515-PA |

|

| 1.3 | 3.2 | 4.5 | 3.5 | ASTM D5470 |

| 96 | 43 | 93 | - | ISO 3219 |

| - | - | - | 15,000 | DIN 53018 |

| -60~150 | -60~150 | -60~150 | -60~150 | - |

| White | Gray | Gray | Gray | - |

| Non-Silicone | Non-Silicone | Non-Silicone | Non-Silicone | - |

| 2.2 | 1.9 | 2.1 | 3.0 | ASTM D792 |

| 350 | - | - | 300 | ASTM D149 |

| >1011 | - | - | >1013 | ASTM D257 |

※Above data are measured data, not guaranteed specifications.

Product Map

*Please swipe left or right to view table below.

-

Product

CategoryProduct

LineProduct Type

(Characteristic)Abbreviation Thermal

conductivity(W/mK)

(MIN〜MAX)Hardness/Viscosity

(Soft~Hard)Thickness(mm)

(MIN〜MAX)Characteristics Delivery as Sheet-Type COH Highly conductive

productsVS

(Very Soft)8.0〜20 ShoreOOO65〜

ShoreOO 350.5〜5.0 Extremely high thermal conductivity

+High softnessStandard Sheet

Custom cut partSheet-Type COH Standard

productsG(Gel)

LB(Low oil Bleed)

S(Standard)1.2〜12 ShoreOO10〜

ShoreA 400.1〜15.0 High Softness

Little oil bleeding

Added stiffeners"Standard Sheet

Custom cut part"Sheet-Type COH High electronic

insulation

productsHI

(High electronic Insulation)1.5〜3.0 ShoreA 80 0.15〜0.35 High electric insulation Standard Sheet

Custom cut partSheet-Type COH Non-silicone

productsN

(Non-Silicone)1.5〜13 ShoreOO50〜

ShoreOO 600.5〜5.0 Free of low molecular

weight siloxaneStandard Sheet

Custom cut partLiquid-Type DP Grease

productsGR

(Grease)1.1〜6.0 16.5(PaS)〜3,090(PaS) - Low viscosity Bottle Liquid-Type DP Putty

productsPT

(Putty)3.5〜8.0 3,500(PaS)〜20,000(PaS) - High viscosity Syringe

CartridgeLiquid-Type DP 2 Component

productsTC

(Two-Component curing)0.55〜5.0 ShoreOO50〜

ShoreA 55- Room temp.

Heat curingSyringe

CartridgeLiquid-Type DP Non-silicone

productsN

(Non-Silicone)1.3〜4.5 43(PaS)〜15,000(PaS) - Free of low molecular

weight siloxaneSyringe

Cartridge

BottleEMI

Shielding

TypeRE Electromagnetic

wave absorption

productsEA

(Electromagnetic Absorption)0.7〜4.0 ShoreOO 39〜

ShoreOO 550.5〜5.0 EMI Shielding

+Heat Dissipation

Electromagnetic wave absorptionStandard Sheet

Custom cut partEMI

Shielding

TypeRE Electromagnetic

wave shielding

productsES

(Electromagnetic Shield)3.0〜5.0 ShoreOO50〜

ShoreOO 550.5〜5.0 EMI Shielding

+Heat Dissipation

Electromagnetic wave shieldingStandard Sheet

Custom cut partDouble-Sided Tapes TP Silicone

productsSi

(Silicone)1.2〜1.8 - 0.15〜0.25 High Adhesion

+Heat DissipationSheet

RollDouble-Sided Tapes TP Non-silicone

productsN

(Non-Silicone)0.9〜2.0 - 0.1〜0.38 High Adhesion

+Heat Dissipation

Free of low molecular weight siloxaneSheet

RollProduct

CategorySheet-Type Sheet-Type Sheet-Type Sheet-Type Liquid-Type Liquid-Type Liquid-Type Liquid-Type EMI Shielding

TypeEMI Shielding

TypeDouble-Sided

TapesDouble-Sided

TapesProduct

LineProduct Type

(Characteristic)Abbreviation Thermal conductivity

(W/mK)

(MIN〜MAX)Hardness/Viscosity

(Soft~Hard)Thickness(mm)

(MIN〜MAX)Characteristics Delivery as COH Highly conductive

productsVS

(Very Soft)8.0〜20 ShoreOOO65〜

ShoreOO 350.5〜5.0 Extremely high thermal conductivity

+High softnessStandard Sheet

Custom cut partCOH Standard products G(Gel)

LB(Low oil Bleed)

S(Standard)1.2〜12 ShoreOO10〜

ShoreA 400.1〜15.0 High Softness

Little oil bleeding

Added stiffenersStandard Sheet

Custom cut partCOH High electronic

insulation productsHI

(High electronic Insulation)1.5〜3.0 ShoreA 80 0.15〜0.35 High electric insulation Standard Sheet

Custom cut partCOH Non-silicone products N

(Non-Silicone)1.5〜13 ShoreOO50〜

ShoreOO 600.5〜5.0 Free of low molecular

weight siloxaneStandard Sheet

Custom cut partDP Grease products GR

(Grease)1.1〜6.0 16.5(PaS)〜3,090(PaS) - Low viscosity Bottle DP Putty products PT

(Putty)3.5〜8.0 3,500(PaS)〜20,000(PaS) - High viscosity Syringe

CartridgeDP 2 Component products TC

(Two-Component curing)0.55〜5.0 ShoreOO50〜

ShoreA 55- Room temp./

Heat curingSyringe

CartridgeDP Non-silicone products N

(Non-Silicone))1.3〜4.5 43(PaS)〜15,000(PaS) - Free of low molecular

weight siloxaneSyringe

Cartridge

BottleRE Electromagnetic wave absorption products EA

(Electromagnetic Absorption)0.7〜4.0 ShoreOO 39〜

ShoreOO 550.5〜5.0 EMI Shielding

+Heat Dissipation

Electromagnetic

wave absorptionStandard Sheet

Custom cut partRE Electromagnetic wave shielding products ES

(Electromagnetic Shield)3.0〜5.0 ShoreOO50〜

ShoreOO 550.5〜5.0 EMI Shielding

+Heat Dissipation

Electromagnetic

wave shieldingStandard Sheet

Custom cut partTP Silicone products Si

(Silicone)1.2〜1.8 - 0.15〜0.25 High Adhesion

+Heat DissipationSheet

RollTP Non-silicone products N

(Non-Silicone)0.9〜2.0 - 0.1〜0.38 High Adhesion

+Heat Dissipation

Free of low molecular

weight siloxanSheet

Roll

Notes

Putty

Grease

2 Component

- Customization

- We also develop custom products to meet our customers’ individual needs. Contact us today!