- TOP

- αGEL Products

- Optical Bonding/Silicone OCA

αGEL Products

Silicone OCA

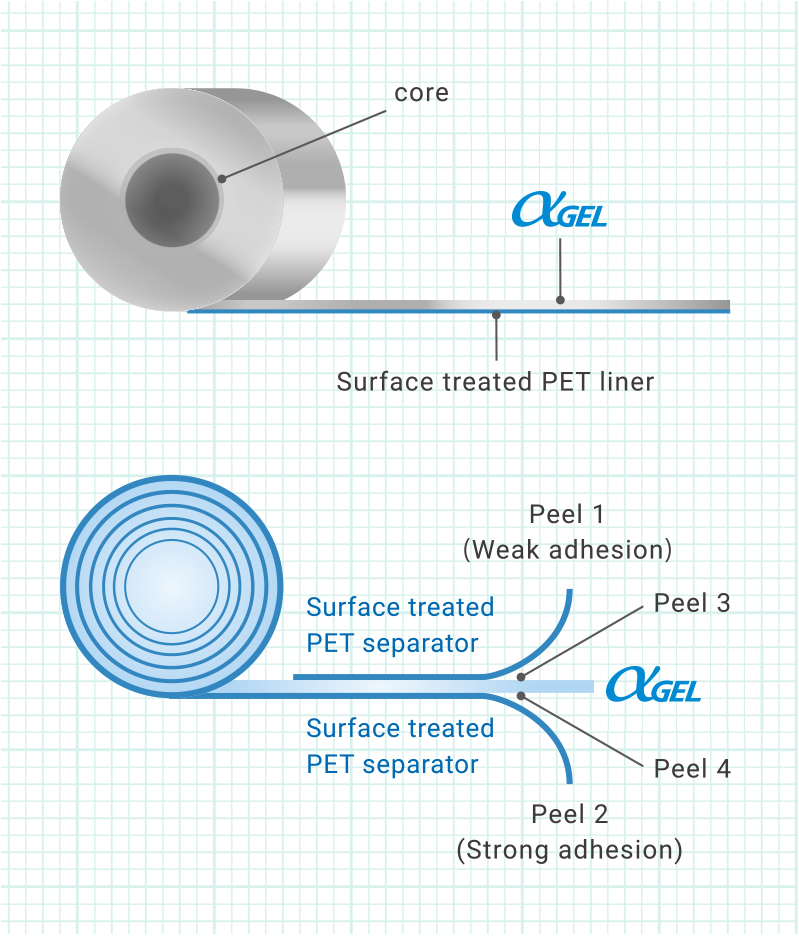

A silicone Optical Clear Adhesive (OCA) that fills air gaps between components in LCD displays, improving brightness and contrast. It is highly resistant to yellowing and shows excellent long-term performance. We sell Silicone OCA in sheets, making it both easy to handle and highly reworkable.

- Characteristics

- ●Made of high-grade silicone, this OCA boasts superior physical properties, providing stable performance.

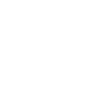

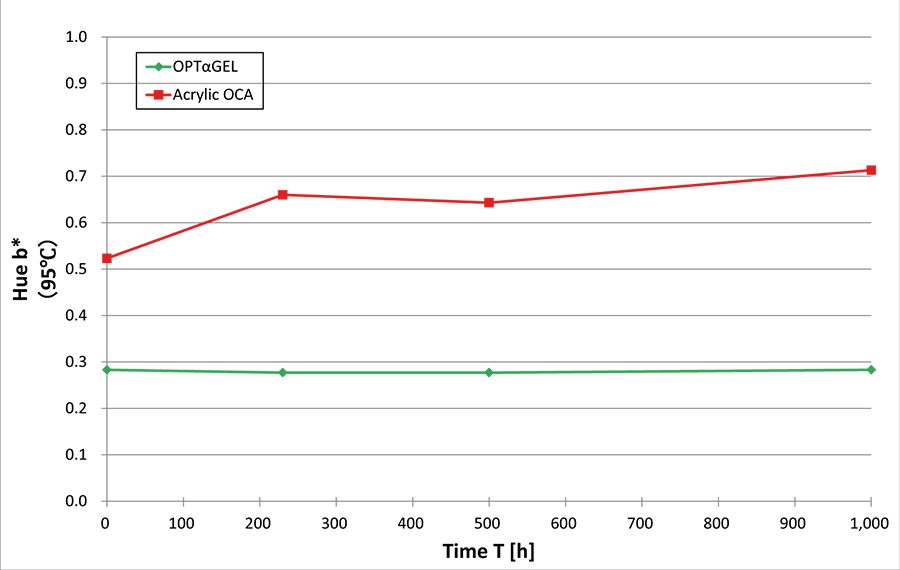

- ●Silicone OCA shows minimal yellowing when exposed to heat and UV radiation. It has low temperature dependence, allowing Silicone OCA to thrive at a wide range of temperatures.

- ●Silicone OCA retains elasticity and reduces stress on display components. This contributes to a more uniform displayed image and improved shock resistance.

- ●Displays can be reworked after bonding with Silicone OCA, improving yields and reducing cost.

- ●Silicone OCA is available in thicknesses between 0.175 mm and 1.8 mm.

- ●The maximum width of Silicone OCA is by 1,280mm. It is suitable for large scale display.

- Application Example

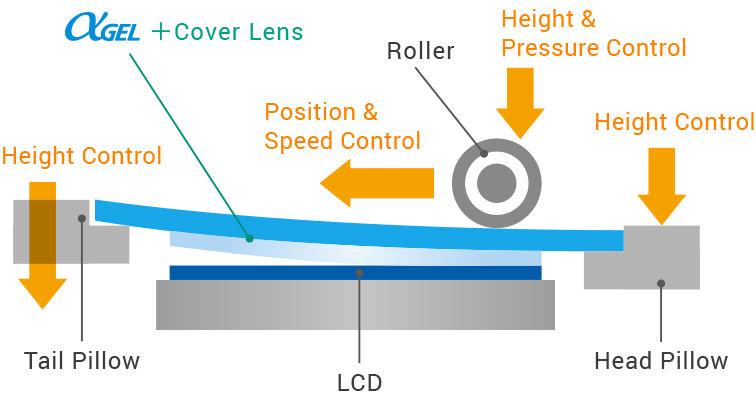

- Inserting Silicone OCA between an LCD unit and the cover lens has many benefits, such as improved shock resistance, stress mitigation, increased contrast, reduced parallax, and improved luminance.

- Technical Information

-

[Transparency (yellowing) long term reliability data (temperature testing)]

[Transparency (yellowing) long term reliability data (UV irradiation testing)]

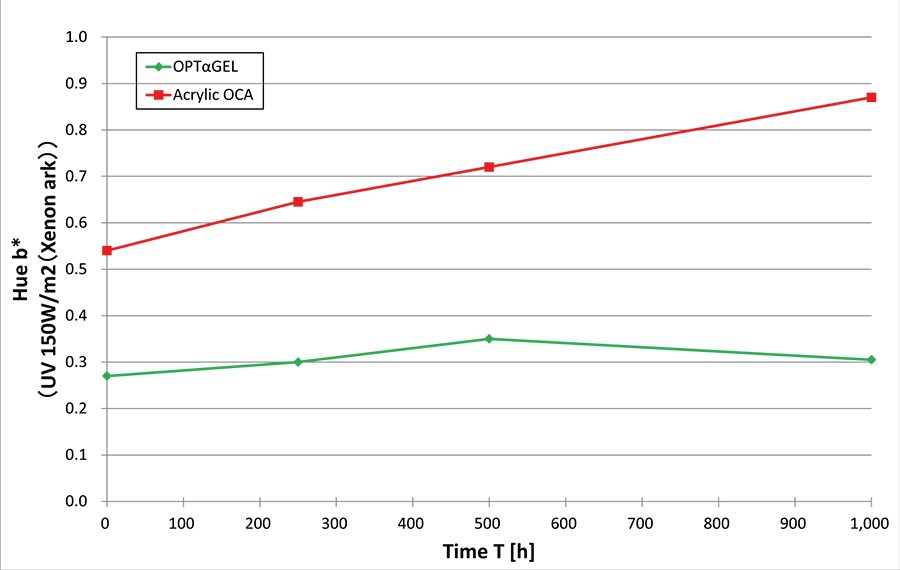

- Product・Packaging

Physical Property Data

*Please swipe left or right to view table below.

[Properties]

| characteristics | Items | Method | Condition① | Condition② | Unit | K120E (-D) |

K95E (-D) |

Notes |

|---|---|---|---|---|---|---|---|---|

| Mechanical Properties |

Hardness | Penetrometer | Cup:40ml | − | 1/10mm | 120 | 95 | JIS K 2207 |

| Young's Modulus | Tensile Tester | φ30mm×t12.7mm | 1mm/min(Compression) | kPa | 22 | 48 | Compressive elastic modulus | |

| Tensile strength at break |

Tensile Tester | K120E:t1.0mm K95E:t1.8mm |

200mm/min | % | 1265 | 1050 | JIS K 6815-1 | |

| Viscoelasticity tanδ | Viscoelasticity measuring device | φ25mm×t1.8mm @10Hz |

20℃ | − | 0.54 | 0.45 | − | |

| 100℃ | − | 0.56 | 0.45 | |||||

| Optical Properties |

Total light transmittance | Haze Meter | K120E:t0.5mm K95E:t1.8mm |

Room Temperature | % | 92.7 | 92.5 | JIS K 7136 |

| 95℃×1000h | % | 92.5 | 91.5 | |||||

| 85℃_85%×1000h | % | 92.4 | 92.2 | |||||

| Spectral light transmittance | Spectrophotometer | K120E:t0.5mm K95E:t1.8mm |

380nm | % | 91 | 91 | JIS K 7105 | |

| 780nm | % | 91 | 91 | |||||

| b* value | Spectrophotometer | K120E:t0.5mm K95E:t1.8mm |

Room Temperature | − | 0.14 | 0.20 | ||

| 95℃×1000h | − | 0.39 | 0.86 | |||||

| 85℃_85%×1000h | − | 0.27 | 0.36 | |||||

| Haze | Haze Meter | K120E:t0.5mm K95E:t1.8mm |

Room Temperature | % | 0.24 | 0.42 | JIS K 7136 | |

| 95℃×1000h | % | 0.33 | 0.61 | |||||

| 85℃_85%×1000h | % | 0.31 | 0.60 | |||||

| Refractive index | Abbe refractometer | 25×25×t0.5mm | 23℃/589nm | − | 1.41 | 1.41 | JIS K 7142 | |

| Others | Specific Gravity | Electronic gravimeter: | φ30mm×t12.7mm | − | − | 0.98 | 0.98 | − |

| characteristics | Items | Method | Condition① | Condition② | Unit | K120E (-D) |

K95E (-D) |

Notes |

|---|---|---|---|---|---|---|---|---|

| Mechanical Properties |

Hardness | Penetrometer | Cup:40ml | − | 1/10mm | 120 | 95 | JIS K 2207 |

| Young's Modulus | Tensile Tester | φ30mm×t12.7mm | 1mm/min(Compression) | kPa | 22 | 48 | Compressive elastic modulus | |

| Tensile strength at break |

Tensile Tester | K120E:t1.0mm K95E:t1.8mm |

200mm/min | % | 1265 | 1050 | JIS K 6815-1 | |

| Viscoelasticity tanδ | Viscoelasticity measuring device | φ25mm×t1.8mm @10Hz |

20℃ | − | 0.54 | 0.45 | − | |

| 100℃ | − | 0.56 | 0.45 | |||||

| Optical Properties |

Total light transmittance | Haze Meter | K120E:t0.5mm K95E:t1.8mm |

Room Temperature | % | 92.7 | 92.5 | JIS K 7136 |

| 95℃×1000h | % | 92.5 | 91.5 | |||||

| 85℃_85%×1000h | % | 92.4 | 92.2 | |||||

| Spectral light transmittance | Spectrophotometer | K120E:t0.5mm K95E:t1.8mm |

380nm | % | 91 | 91 | JIS K 7105 | |

| 780nm | % | 91 | 91 | |||||

| b* value | Spectrophotometer | K120E:t0.5mm K95E:t1.8mm |

Room Temperature | − | 0.14 | 0.20 | ||

| 95℃×1000h | − | 0.39 | 0.86 | |||||

| 85℃_85%×1000h | − | 0.27 | 0.36 | |||||

| Haze | Haze Meter | K120E:t0.5mm K95E:t1.8mm |

Room Temperature | % | 0.24 | 0.42 | JIS K 7136 | |

| 95℃×1000h | % | 0.33 | 0.61 | |||||

| 85℃_85%×1000h | % | 0.31 | 0.60 | |||||

| Refractive index | Abbe refractometer | 25×25×t0.5mm | 23℃/589nm | − | 1.41 | 1.41 | JIS K 7142 | |

| Others | Specific Gravity | Electronic gravimeter: | φ30mm×t12.7mm | − | − | 0.98 | 0.98 | − |

※Silicone oil may bleed depending upon conditions.

※Low molecular siloxane is included in this product which basically composed of silicone.

※Above data are measured data, not guaranteed specifications.

■Transmittance after

environmental test

(Result after 1000 hours)

*Please swipe left or right to view table below.

| Measurement wavelength |

Initial | High temperature exposure |

Hot and humid climate |

Heat cycle | Light resistance |

Low temperature storage |

|---|---|---|---|---|---|---|

| 85℃ | 60℃× 90%RH |

-40℃ ⇔85℃ |

150W /m2 |

-40℃ | ||

| 400nm | 91 | 91 | 91 | 91 | 91 | 91 |

| 800nm | 91 | 91 | 91 | 91 | 91 | 91 |

| Measurement wavelength |

Initial | High temperature exposure |

Hot and humid climate |

Heat cycle | Light resistance |

Low temperature storage |

|---|---|---|---|---|---|---|

| 85℃ | 60℃× 90%RH |

-40℃ ⇔85℃ |

150W /m2 |

-40℃ | ||

| 400nm | 91 | 91 | 91 | 91 | 91 | 91 |

| 800nm | 91 | 91 | 91 | 91 | 91 | 91 |

Unit:%

■Peel strength(Peel3)

Product Map

*Please swipe left or right to view table below.

| Item | Thickness(mm) | Width(mm) | Length(M) | Core(inch) | Liner | Adhesion Strength vs liner(N/20mm) | ||

|---|---|---|---|---|---|---|---|---|

| Liner | Effective | Peel1 (Weak Adhesion) |

Peel2 (Strong Adhesion) |

|||||

| K120E (-D) |

t0.175/t0.2/t0.25/ t0.3/t0.5 |

500 | 460 | 50 | 3/6 | Liner on one-side |

0.05 | 0.7 |

| K120E (-D) |

t0.8/t1.0 | 500 | 440 | 25 | 3/6 | Liner on one-side |

0.05 | 0.7 |

| K95E (-D) |

t1.2/t1.5/t1.8 | 500 | 400 | 25 | 3/6 | Liner on one-side |

0.03 | 0.5 |

| Item |

|---|

| K120E (-D) |

| K120E (-D) |

| K95E (-D) |

| Thickness(mm) | Width(mm) | Length(M) | Core(inch) | Liner | Adhesion Strength vs liner(N/20mm) | ||

|---|---|---|---|---|---|---|---|

| Liner | Effective | Peel1(Weak Adhesion) | Peel2(Strong Adhesion) | ||||

| t0.175/t0.2/t0.25/ t0.3/t0.5 |

500 | 460 | 50 | 3/6 | Liner on one-side | 0.05 | 0.7 |

| t0.8/t1.0 | 500 | 440 | 25 | 3/6 | Liner on one-side | 0.05 | 0.7 |

| t1.2/t1.5/t1.8 | 500 | 400 | 25 | 3/6 | Liner on one-side | 0.03 | 0.5 |

Notes

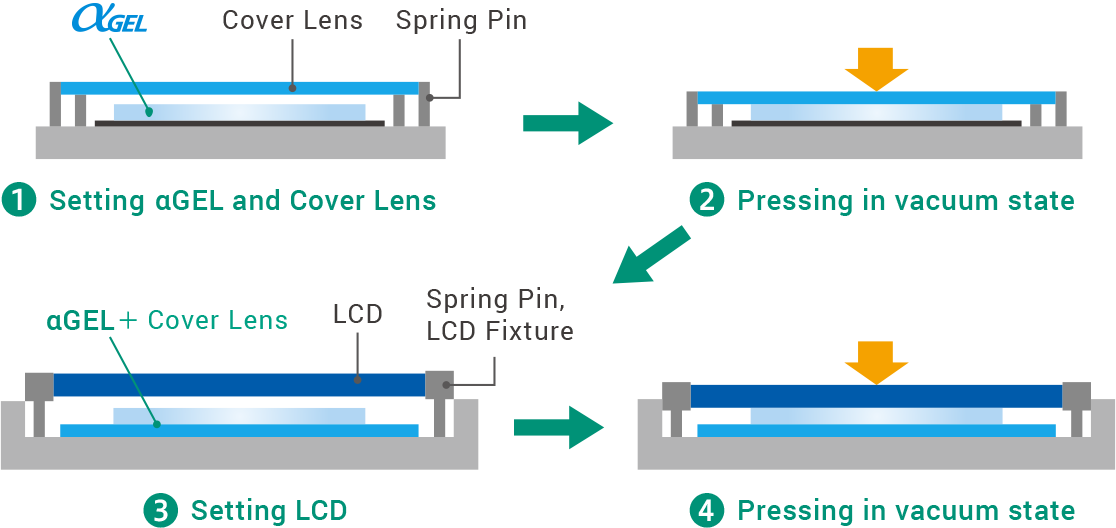

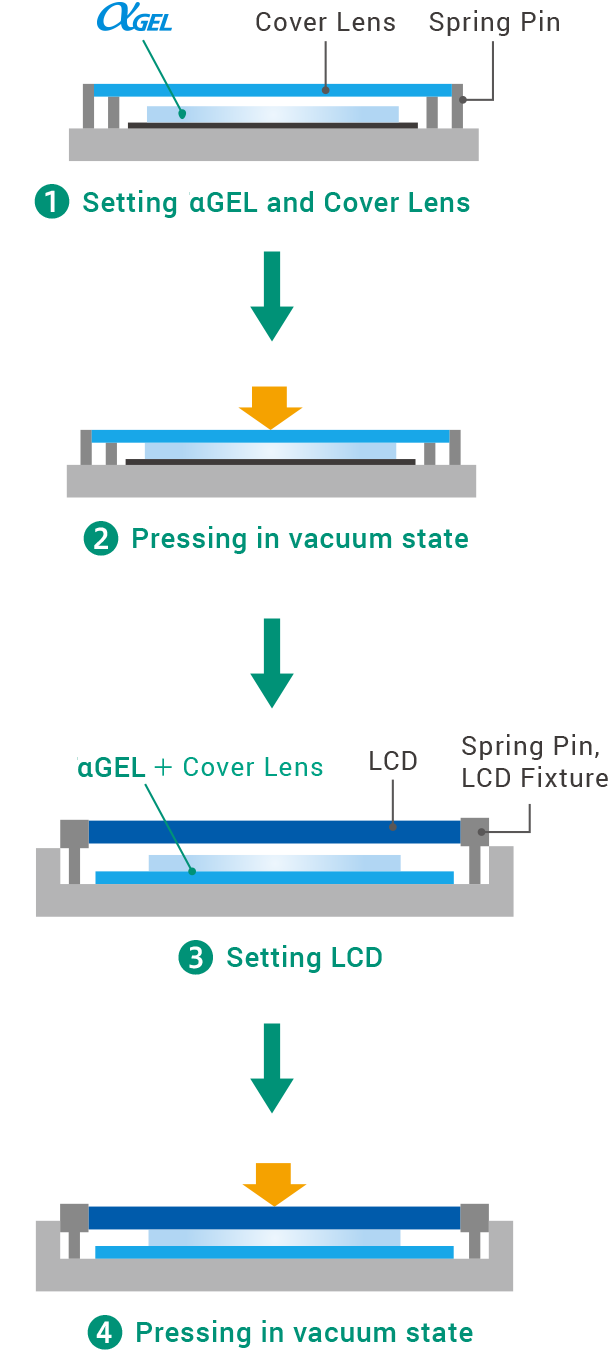

- Vacuum Lamination

-

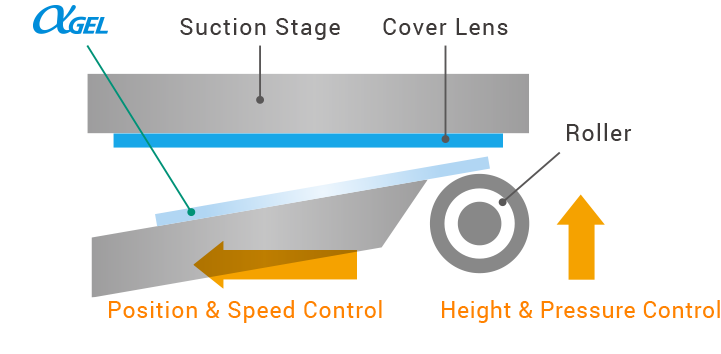

- Non-Vacuum Lamination (Roller Lamination with Autoclave)

-

Laminating αGEL and Cover Lens

LCDとLaminating αGEL and LCD

- Customization

- We also develop custom products to meet our customers’ individual needs. Contact us today!