- TOP

- Support & Inquiries

- Technical Glossary

- Styrene-butadiene Rubber

Technical Glossary

Styrene-butadiene Rubber

[Styrene-butadiene Rubber]

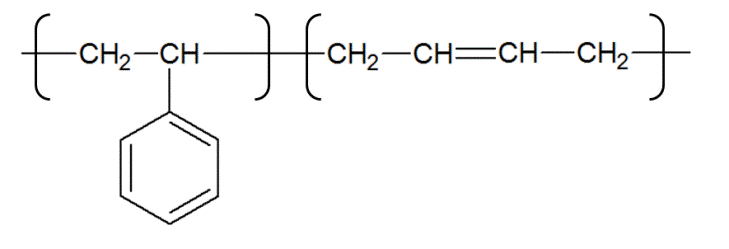

Styrene-butadiene rubber (SBR) is a rubber with styrene and butadiene as its main components and which represents 80% of all synthetic rubber produced in the world. First developed in Germany in 1930 as “Buna S”, it became widely used as automobiles became popular.

Manufacturing methods include emulsion polymerization and solution polymerization. SBR derived from the standard emulsion polymerization method generally has a styrene content of 23.5%. When using emulsion polymerization, the proportion of butadiene bonds varies depending on the reaction temperature. When synthesized at low temperature (cold rubber), which has become the mainstream method, the number of trans linkages increases.

Solution polymerized SBR is also known as a raw material for low fuel consumption tires.

During solution polymerization, a random copolymer and a block copolymer, in this case a thermoplastic elastomer react. SEBS with improved weather resistance with a hydrogenated double bond between the block copolymers thermoplastic elastomer is also widely used.

SBR has excellent heat and abrasion resistance, mechanical strength, and stable product quality. It is also inexpensive and easy to process.

On the other hand, its tear strength and cold, organic solvents and ozone resistance are somewhat inferior to other products.

Although it is mainly used in car tires, SBR is also used in large quantities in industrial products such as belts and hoses.

- Customization

- We also develop custom products to meet our customers’ individual needs. Contact us today!